14 Test Operation, Adjustment, Maintenance and Troubleshooting

14.5 Troubleshooting with LEDs

211

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

11

High-Speed

Counters

12

Output Wiring

13

Wiring for

Various Uses

14

Test Run,

Maintenance,

Troubleshooting

15

Input/Output

Powered

Extension Units

16

Input/Output

Extension

Blocks

17

Extension

Power Supply

Unit

18

Other Extension

Units and

Options

19

Display Module

20

Terminal Block

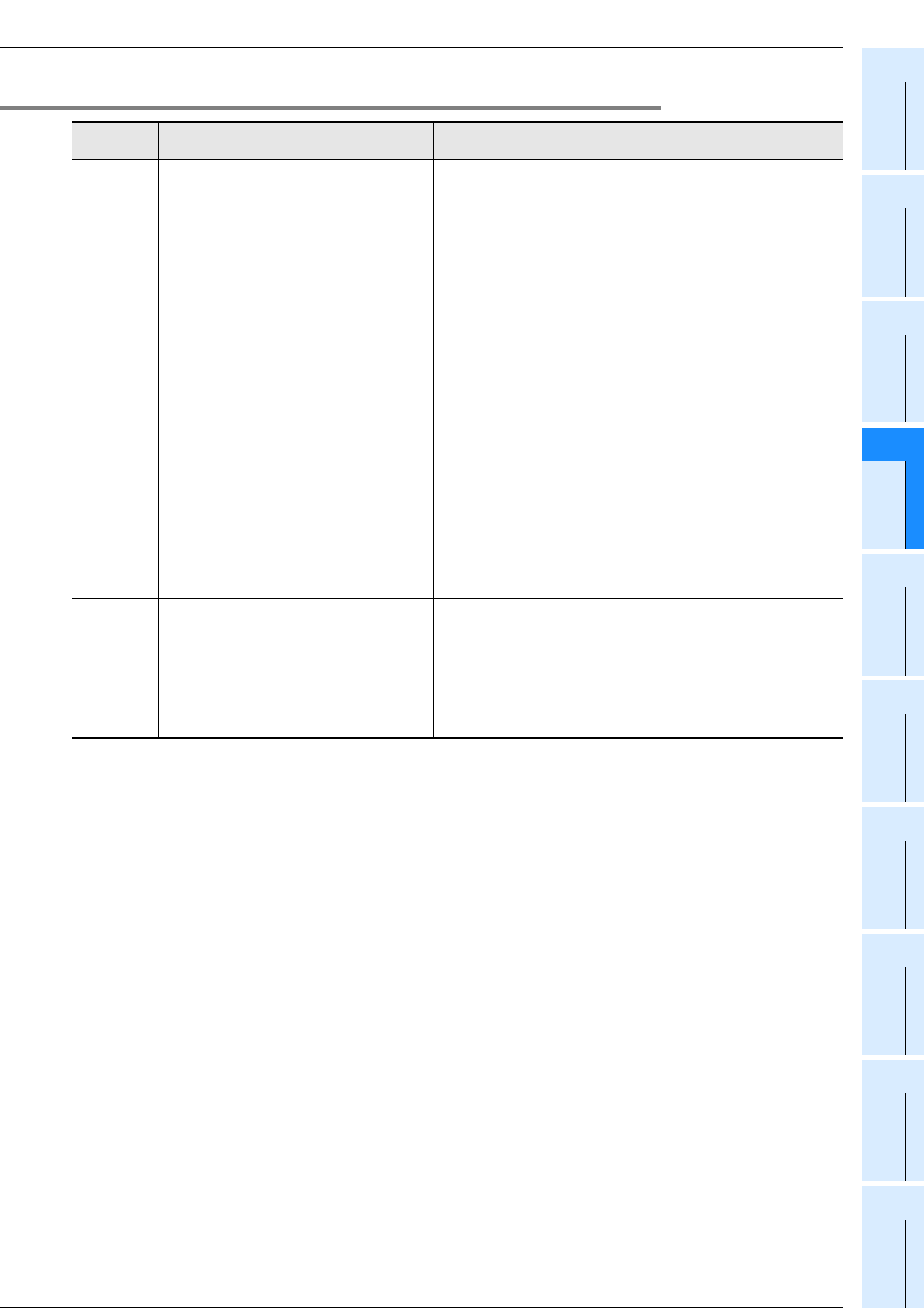

14.5.3 ERR LED [on/flashing/off]

State of

LED

State of PLC Remedies

On

A watchdog timer error may have occurred, or

the hardware of the PLC may be damaged.

1) Stop the PLC, and re-apply power.

If ERR LED goes off, a watchdog timer error may have occurred.

Take any of the following measures.

- Review the program.

The maximum value (D8012) of the scan time should not exceed

the setting (D8000) of the watchdog timer.

- Check that the input used for input interruption or pulse catch is

not being abnormally turned on and off in one scan.

- Check that the frequency of the pulse (duty of 50%) input to the

high-speed counter does not exceed the specified range.

- Add the WDT instructions.

Add some WDT instructions to the program, and reset the

watchdog timer several times in one scan.

- Change the setting of the watchdog timer.

Change the watchdog timer setting (D8000) in the program so

that the setting is larger than the maximum value of the scan time

(D8012).

2) Remove the PLC and supply power to it from another power supply

on a desk.

If the ERR LED goes off, noise may have affected the PLC.

Take the following measures.

- Check the ground wiring, and reexamine the wiring route and

installation location.

- Fit a noise filter onto the power supply line.

3) If the ERR LED does not go off even after the measures stated in

(1) and (2) are taken, consult your local Mitsubishi Electric

representative.

Flashing

One of the following errors has occurred in the

PLC.

• Parameter error

• Syntax error

• Ladder error

Perform PLC diagnosis and program check with the programming tool.

For the remedies, refer to 14.6 Judgment by Error Codes and

Representation of Error Codes.

Off No errors that stop the PLC have occurred.

If the operations of the PLC are abnormal, perform PLC diagnosis and

program check with the programming tool.

An I/O error, Comms error or Runtime error may have occurred.