14 Test Operation, Adjustment, Maintenance and Troubleshooting

14.6 Judgment by Error Codes and Representation of Error Codes

219

FX3G Series Programmable Controllers

User's Manual - Hardware Edition

11

High-Speed

Counters

12

Output Wiring

13

Wiring for

Various Uses

14

Test Run,

Maintenance,

Troubleshooting

15

Input/Output

Powered

Extension Units

16

Input/Output

Extension

Blocks

17

Extension

Power Supply

Unit

18

Other Extension

Units and

Options

19

Display Module

20

Terminal Block

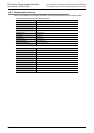

Operation error [M8067(D8067)]

6742

Continues

operation

Variation of measured value exceeds limit.

( PV < -32768 or +32767 < PV)

<PID operation is continued.>

The operation is continued with each parameter set to the

maximum or minimum value.

6743

Deviation exceeds limit.

(EV < -32768 or +32767 < EV)

6744

Integral result exceeds limit.

(Outside range from -32768 to +32767)

6745 Derivative value exceeds limit due to derivative gain (KD).

6746

Derivative result exceeds limit.

(Outside range from -32768 to +32767)

6747

PID operation result exceeds limit.

(Outside range from -32768 to +32767)

6748

PID output upper limit set value < PID output lower limit set

value.

<Transpose of output upper limit value and output lower limit

value. PID operation is continued.>

Check whether the target setting contents are correct.

6749

Abnormal PID input variation alarm set value or output

variation alarm set value (Set value < 0)

<Alarm output is not given. PID operation is continued.>

Check whether the target setting contents are correct.

6750

<Step response method>

Improper auto tuning result

<Auto tuning is finished. PID operation is started.>

• The deviation at start of auto tuning is 150 or less.

• The deviation at end of auto tuning is 1/3 or more of the

deviation at start of auto tuning.

Check the measured value and target value, and then execute

auto tuning again.

6751

<Step response method>

Auto tuning operation direction mismatch

<Auto tuning is forcibly finished. PID operation is not

started.>

The operation direction estimated from the measured value at

the start of auto tuning was different from the actual operation

direction of the output during auto tuning.

Correct the relationship among the target value, output value

for auto tuning, and the measured value, and then execute

auto tuning again.

6752

<Step response method>

Improper auto tuning result

<Auto tuning is finished. PID operation is not started.>

Because the set value was fluctuated during auto tuning, auto

tuning was not executed correctly.

Set the sampling time to a value larger than the output change

cycle, or set a larger value for the input filter constant.

After changing the setting, execute auto tuning again.

6753

<Limit cycle method>

Auto tuning operation direction mismatch

<Auto tuning is forcibly finished. PID operation is not

started.>

Check whether the target setting contents are correct.

6754

<Limit cycle method>

Abnormal PV threshold (hysteresis) set value for auto tuning

(SHPV < 0)

6755

<Limit cycle method>

Abnormal auto tuning transfer status

(Data of device controlling transfer status is abnormally

overwritten.)

<Auto tuning is forcibly finished. PID operation is not

started.>

Ensure that devices occupied by PID instruction are not

overwritten in the program.

6756

<Limit cycle method>

Abnormal result due to excessive auto tuning measurement

time ( on > , on < 0, < 0)

<Auto tuning is forcibly finished. PID operation is not

started.>

The auto tuning time is longer than necessary.

Increase the difference (ULV - LLV) between the upper limit

and lower limit of the output value for auto tuning, set a

smaller value to the input filter constant ( ), or set a smaller

value to the PV threshold (SHPV) for auto tuning, and then

check the result for improvement.

Error

code

PLC

operation

at error

occurrence

Contents of error Action