Teledyne API - Model 200EH/EM Operation Manual Calibration Procedures

157

7.1.4. DATA RECORDING DEVICES

A strip chart recorder, data acquisition system or digital data acquisition system should be used to record data

from the serial or analog outputs of the M200EH/EM. If analog readings are used, the response of the recording

system should be checked against a NIST traceable voltage source or meter. Data recording devices should be

capable of bi-polar operation so that negative readings can be recorded. For electronic data recording, the

M200EH/EM provides an internal data acquisition system (iDAS), which is described in detail in Section 6.7.

APICOM, a remote control program, is also provided as a convenient and powerful tool for data handling,

download, storage, quick check and plotting.

7.1.5. NO

2

CONVERSION EFFICIENCY

To ensure accurate operation of the M200EH/EM, it is important to check the NO

2

conversion efficiency (CE)

periodically and to update this value as necessary.

The default setting for the NO

2

converter efficiency is 1.0000. For the analyzer to function correctly, the

converter efficiency must be between 0.9600 and 1.0200 (96-102% conversion efficiency) as per US-EPA

requirements. If the converter’s efficiency is outside these limits, the NO

2

converter should be replaced.

NOTE

The currently programmed CE is recorded along with the calibration data in the iDAS for

documentation and performance analysis

7.1.5.1. Determining / Updating the NO

2

Converter Efficiency

The following procedure will cause the Model 200EH/EM to automatically calculate the current NO

2

conversion

efficiency.

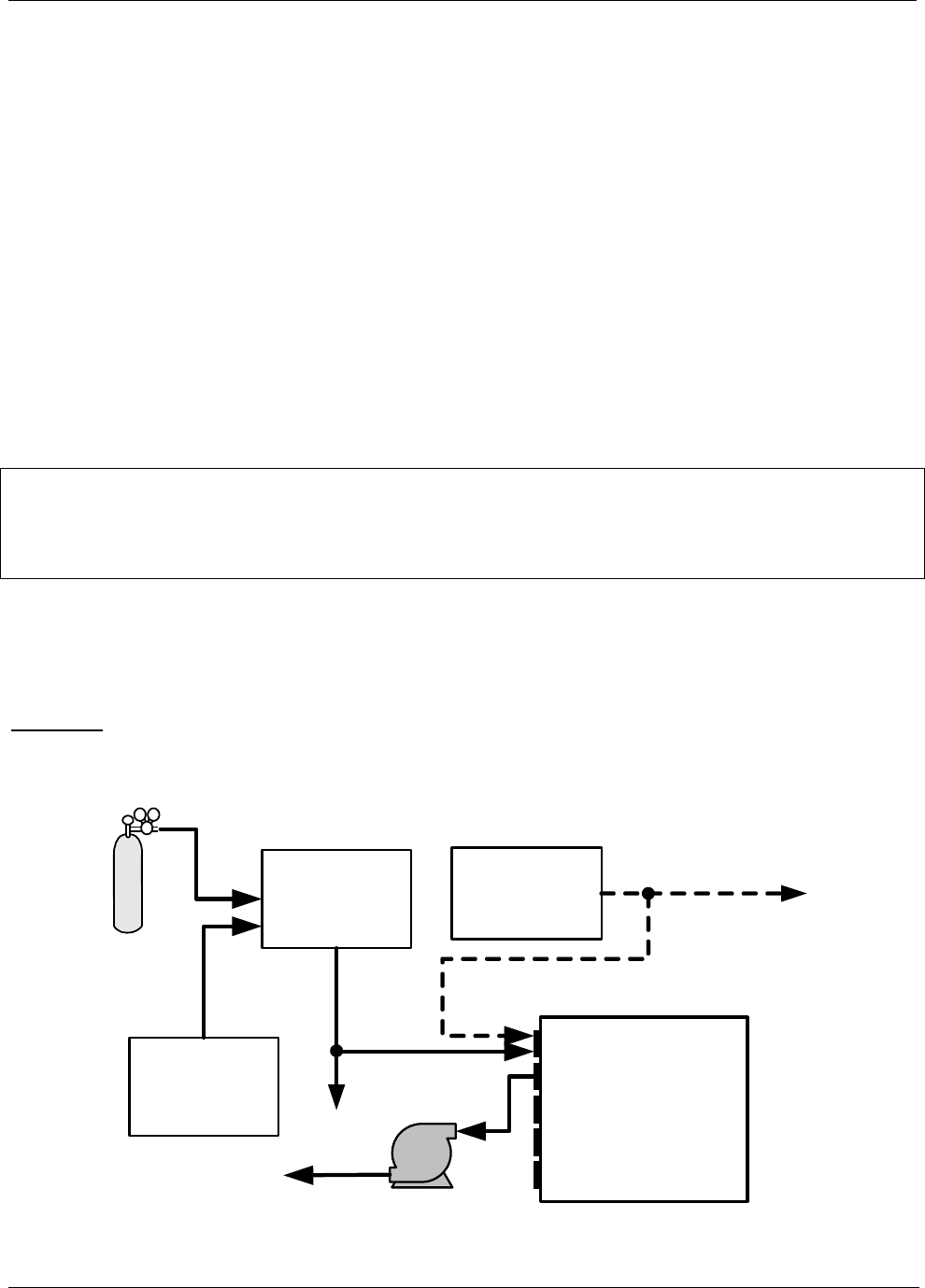

STEP ONE:

Connect a source of calibrated NO

2

span gas as shown below.

Source of

SAMPLE GAS

Removed during

calibration

MODEL

200EH/EM

SAMPLE

EXHAUST

PUMP

MODEL 700

Gas Dilution

Calibrator

VENT

MODEL 701

Zero Gas

Generator

NO

x

Gas

(High Concentration)

VENT here if input

is pressurized

Figure 7-1: Gas Supply Setup for Determination of NO

2

Conversion Efficiency

04521C (DCN5731)