Getting Started Teledyne API - Model 200EH/EM Operation Manual

20

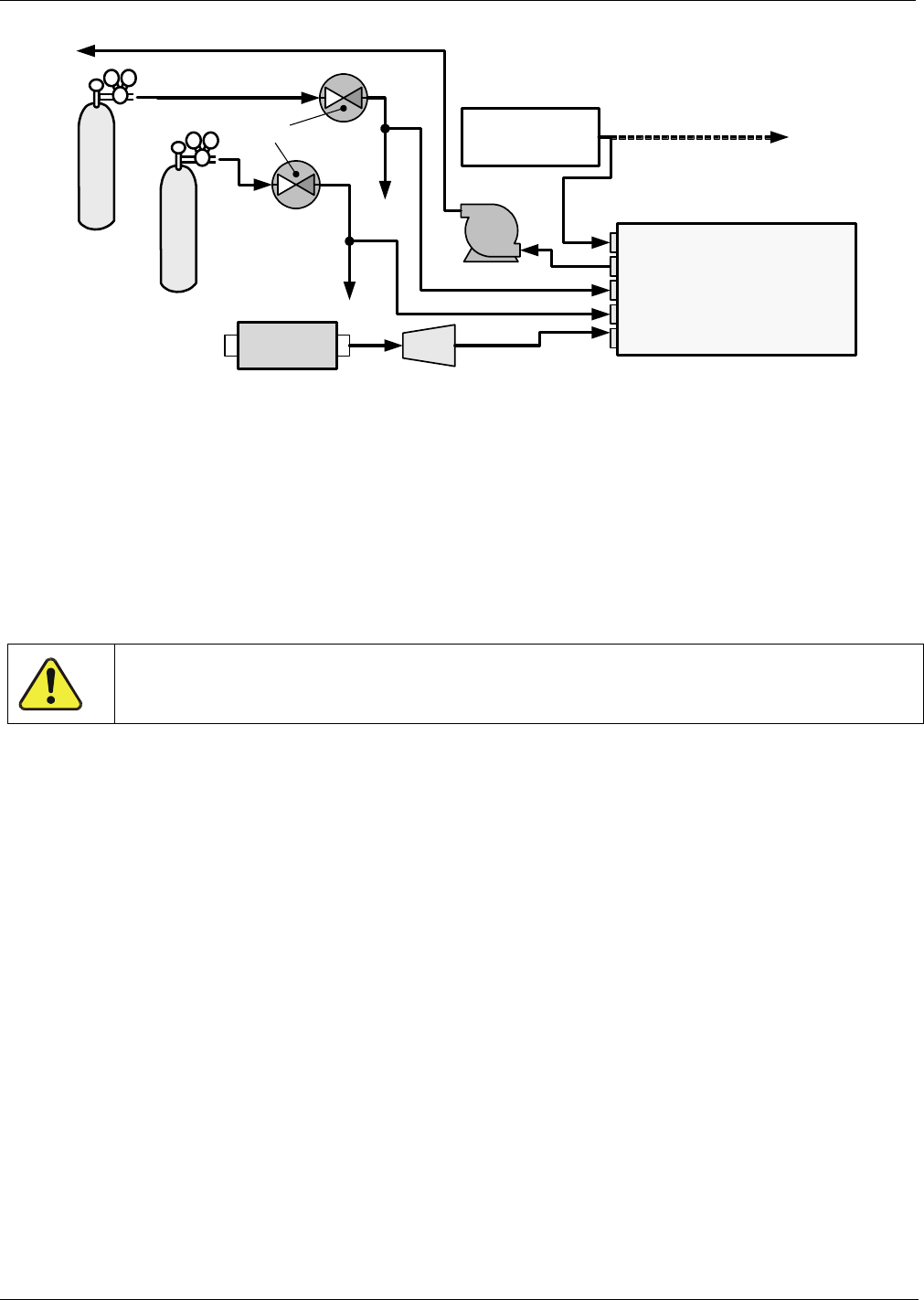

VENT here if input

is pressurized

Source of

SAMPLE Gas

PUMP

VENT

MODEL

200EH/EM

Sample

Exhaust

High Span Point

Low Span Point

Zero Air

Calibrated NO

at HIGH Span

Concentration

Calibrated NO

at LOW Span

Concentration

Filter

External Zero

Air Scrubbe

r

VENT

On/Off

Valves

Figure 3-12: Pneumatic Connections–With 2-Span point Option (52) –Using Bottled Span Gas

Once the appropriate pneumatic connections have been made, check all pneumatic fittings for leaks using the

procedures defined in Section 11.5.

3.2. INITIAL OPERATION

CAUTION!

If the presence of ozone is detected at any time, call Teledyne API Customer Service as soon as possible:

800-324-5190 or email: api-customerservice@teledyne.com

If you are unfamiliar with the theory of operation of the M200EH/EM analyzer, we recommend that you read

Chapter 10 before proceeding. For information on navigating the analyzer’s software menus, see the me

nu

trees described in Appendix A-1.

3.2.1. STARTUP

After electrical and pneumatic connections are made, turn on the instrument and supply power to the external

pump.

The exhaust and PMT cooler fans should start.

The display should immediately display a single, horizontal dash in the upper left corner of the display.

This will last approximately 30 seconds while the CPU loads the operating system.

Once the CPU has completed this activity, it will begin loading the analyzer firmware and configuration data.

During this process, a string of messages will appear on the analyzer’s front panel display as shown in Figure

3-13. The analyzer should

automatically switch to SAMPLE mode after completing the boot-up sequence and

start monitoring NO

X

, NO, NO

2

gases.

04521C (DCN5731)