Teledyne API - Model 200EH/EM Operation Manual Theory of Operation

199

GAS FLOW

CONTROL

ASSEMBLIES

SAMPLE

PRESSURE

SENSOR

VACUUM

PRESSURE

SENSOR

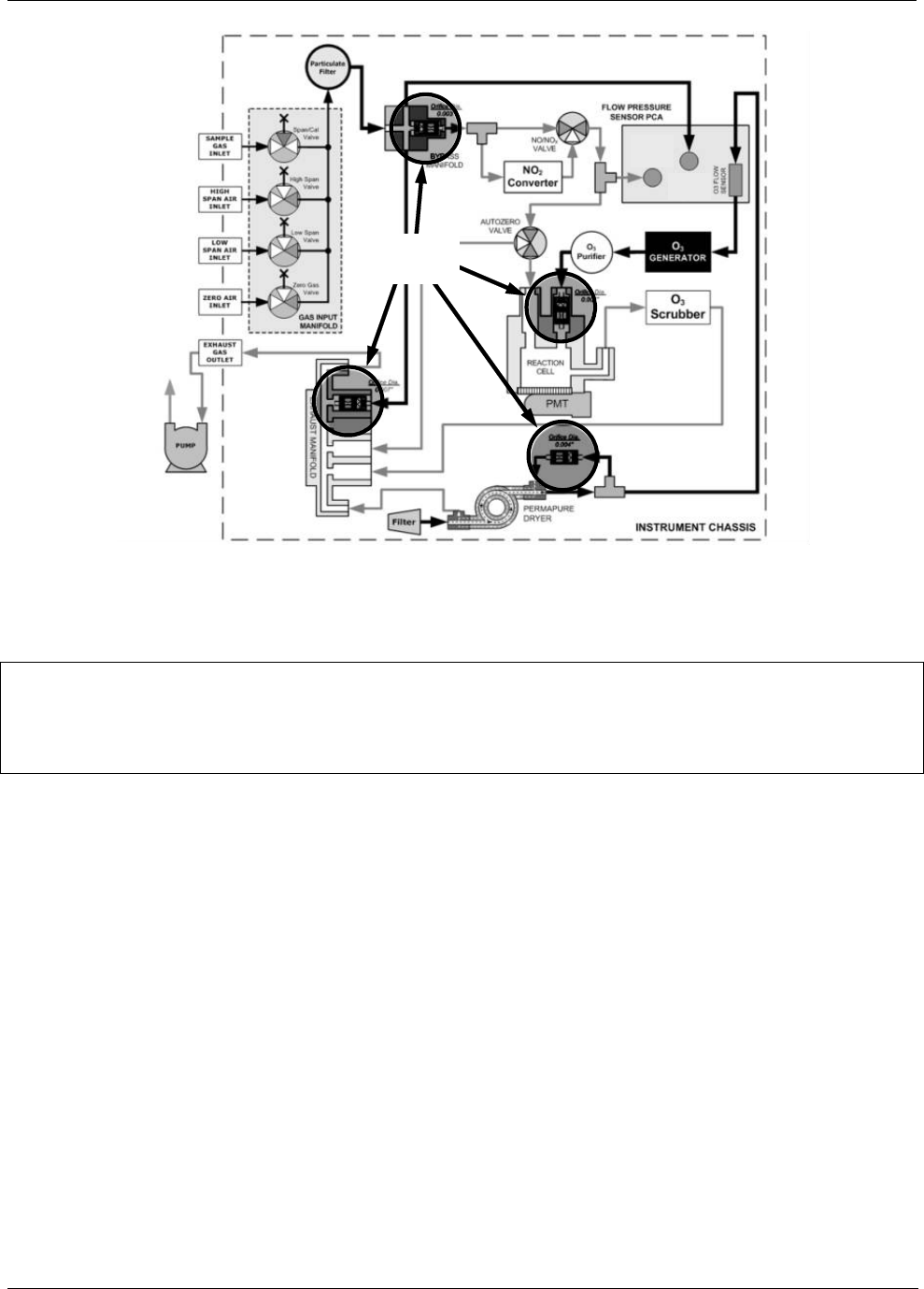

Figure 10-10-9: Location of Gas Flow Control Assemblies for M200EH with Second Span Point Option 52

NOTE:

Location of flow control assemblies in the M200EH/EM with zero/span option 50

installed are the same as shown in Figures 10-6 and 10-7.

10.3.3.1. Critical Flow Orifice

The most important component of the flow control assemblies is the critical flow orifice.

Critical flow orifices are a remarkably simple way to regulate stable gas flow rates. They operate without moving

parts by taking advantage of the laws of fluid dynamics. By restricting the flow of gas though the orifice, a

pressure differential is created. This pressure differential combined with the action of the analyzer’s pump draws

the gas through the orifice.

As the pressure on the downstream side of the orifice (the pump side) continues to drop, the speed that the gas

flows though the orifice continues to rise. Once the ratio of upstream pressure to downstream pressure is

greater than 2:1, the velocity of the gas through the orifice reaches the speed of sound. As long as that ratio

stays at least 2:1 the gas flow rate is unaffected by any fluctuations, surges, or changes in downstream pressure

because such variations only travel at the speed of sound themselves and are therefore cancelled out by the

sonic shockwave at the downstream exit of the critical flow orifice.

04521C (DCN5731)