Teledyne API - Model 200EH/EM Operation Manual Getting Started

19

1. Attach a 1/4" exhaust line between the external pump exhaust port of the analyzer.

2. Attach an additional 1/4" exhaust port of the pump.

CAUTION

The exhaust from the analyzer needs to be vented outside the shelter or immediate area

surrounding the instrument and conform to all safety requirements using a maximum of

10 meters of 1/4” PTFE tubing.

3. Attach a sample inlet line to the sample inlet port. Ideally, the pressure of the sample gas should be

equal to ambient atmospheric pressure.

NOTE

Maximum pressure of any gas at the sample inlet should not exceed 1.5 in-Hg above

ambient pressure and ideally should equal ambient atmospheric pressure.

In applications where the sample gas is received from a pressurized manifold, a vent

must be provided to equalize the sample gas with ambient atmospheric pressure before

it enters the analyzer. The vented gas needs to be routed outside the immediate area

or shelter surrounding the instrument.

4. Once the appropriate pneumatic connections have been made, check all pneumatic fittings for leaks

using a procedure similar to that defined in Section 11.5.1.

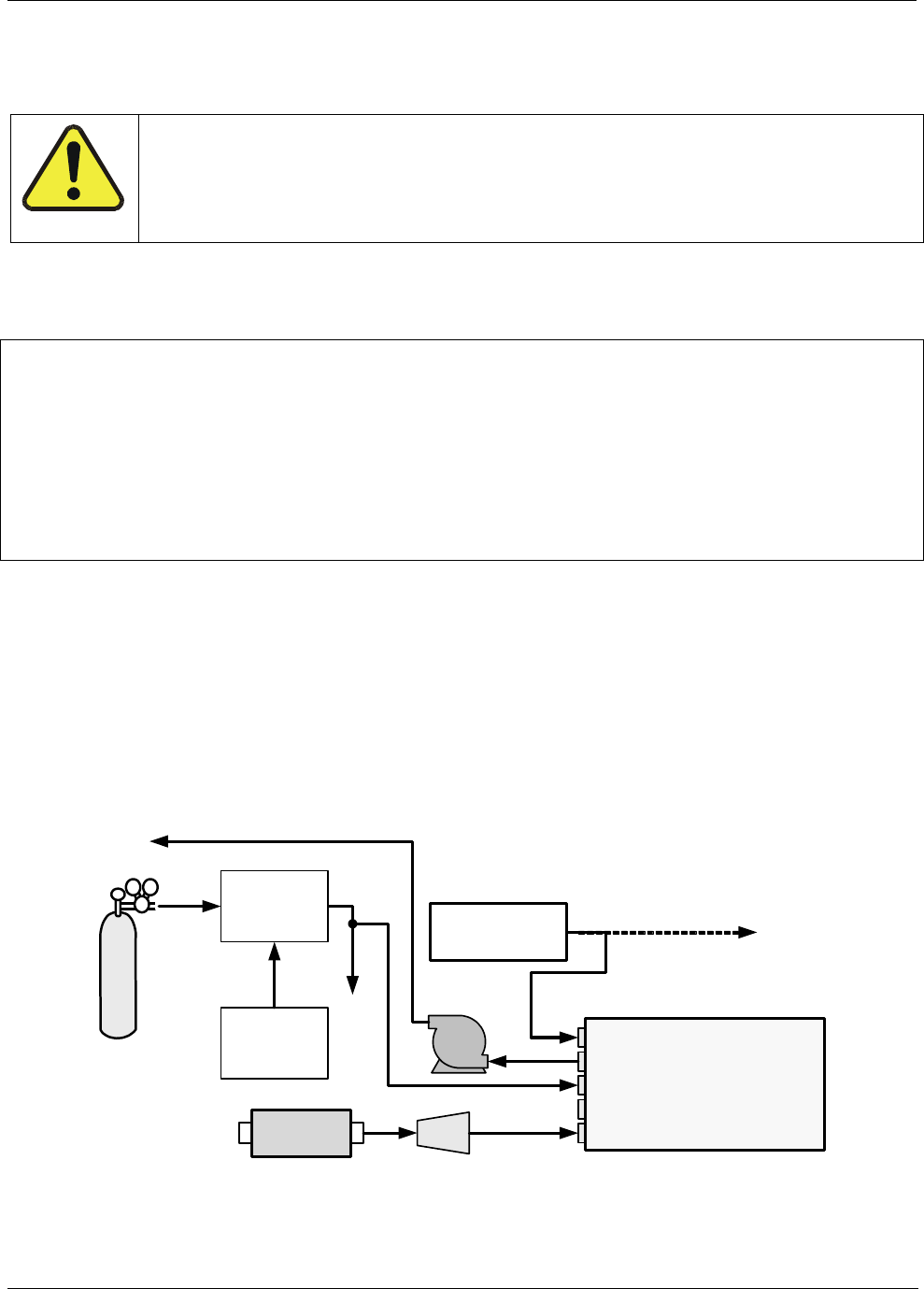

3.1.3.3. Connections with Internal Valve Options Installed

If your analyzer is equiped with either the zero/span valve option (50) or the 2-span point valve option(52), the

pneumatic connections should be made as shown in figures 3-11 & 3-12:

VENT here if input

is pressurized

Source of

SAMPLE Gas

PUMP

MODEL

200EH/EM

Sample

Exhaust

Span Point

Zero Air

Calibrated NO

at HIGH Span

Concentration

Filter

External Zero

Air Scrubbe

r

VENT

MODEL 700

Gas Dilution

Calibrator

MODEL 701

Zero Gas

Generator

Figure 3-11: Pneumatic Connections–With Zero/Span Valve Option (50)

04521C (DCN5731)