Calibration Procedures Teledyne API - Model 200EH/EM Operation Manual

172

7.8. CALIBRATION QUALITY ANALYSIS

After completing one of the calibration procedures described above, it is important to evaluate the analyzer’s

calibration

SLOPE and OFFSET parameters. These values describe the linear response curve of the analyzer,

separately for NO and NO

X

. The values for these terms, both individually and relative to each other, indicate the

quality of the calibration. To perform this quality evaluation, you will need to record the values of the following

test functions (Section 6.2.1 or Appendix A-3), all of which are aut

omatically stored in the iDAS channel

CALDAT for data analysis, documentation and archival.

NO OFFS

NO SLOPE

NOX OFFS

NOX SLOPE

Make sure that these parameters are within the limits listed in Table 7-5 and frequently compare them to those

values on the Final Test and Checkout Sheet that came attached to your manual, which should not be

significantly different. If they are, refer to the troubleshooting Chapter 11.

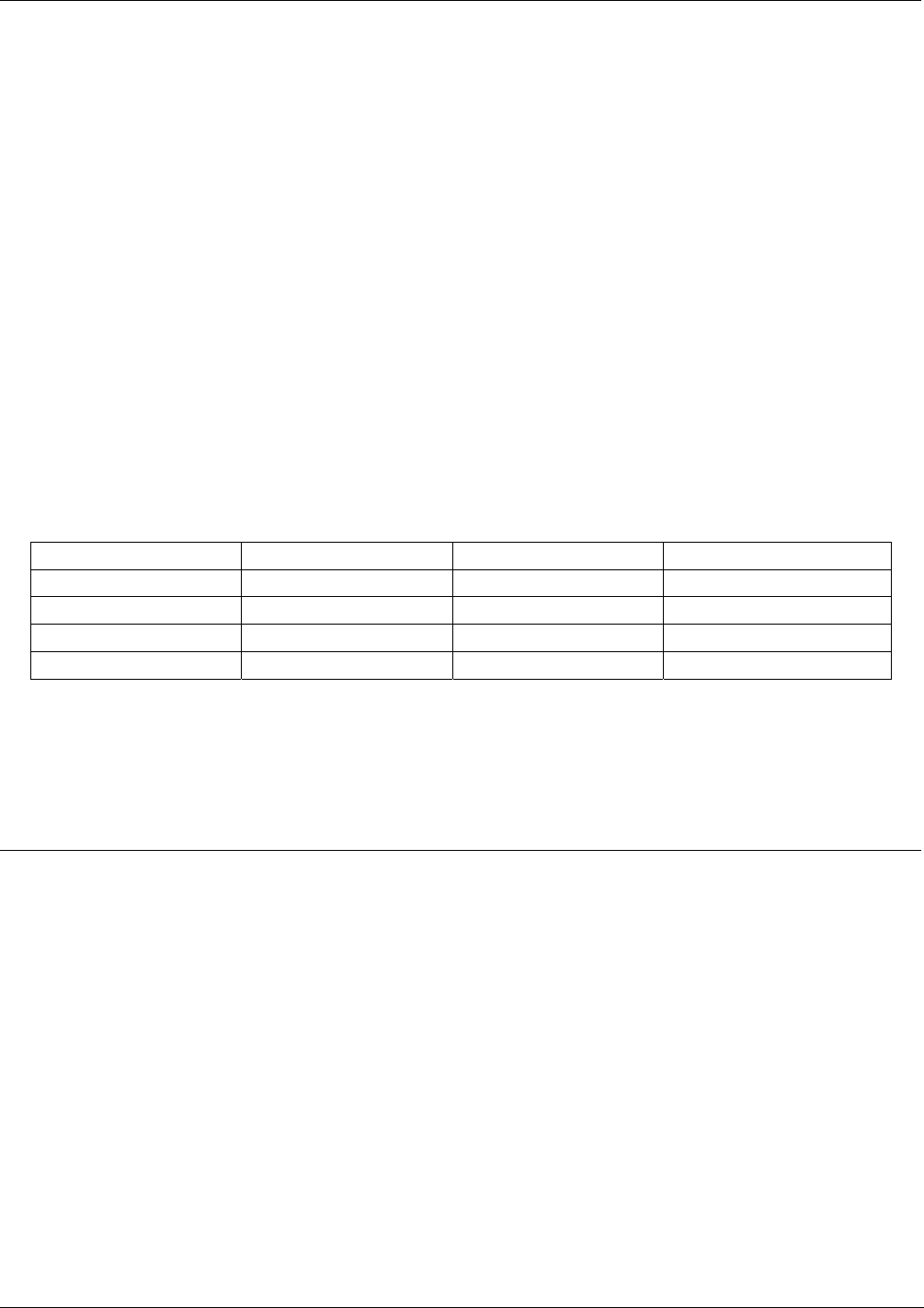

Table 7-5: Calibration Data Quality Evaluation

FUNCTION MINIMUM VALUE OPTIMUM VALUE MAXIMUM VALUE

NOX SLOPE

-0.700 1.000 1.300

NO SLOPE

-0.700 1.000 1.300

NOX OFFS

-20.0 mV 0.0 mV 150.0 mV

NO OFFS

-20.0 mV 0.0 mV 150.0 mV

The default iDAS configuration records all calibration values in channel CALDAT as well as all calibration check

(zero and span) values in its internal memory. Up to 200 data points are stored for up 4 years of data (on

weekly calibration checks) and a lifetime history of monthly calibrations. Review these data to see if the zero

and span responses change over time. These channels also store the STABIL value (standard deviation of NO

X

concentration) to evaluate if the analyzer response has properly leveled off during the calibration procedure.

Finally, the CALDAT channel also stores the converter efficiency for review and documentation.

USER NOTES:

04521C (DCN5731)