Troubleshooting & Repair Teledyne API - Model 200EH/EM Operation Manual

232

11.1.1. WARNING MESSAGES

The most common and/or serious instrument failures will result in a warning message displayed on the front

panel. Table A-2 in Appendix A.3 contains a list of warning messages, along with their meaning and

recommended corrective action.

It should be noted that if more than two or three warning messages occur at the same time, it is often an

indication that some fundamental analyzer sub-system (power supply, relay board, motherboard) has failed

rather than an indication of the specific failures referenced by the warnings. In this case, a combined-error

analysis needs to be performed.

The analyzer will alert the user that a warning is active by displaying the keypad labels

MSG and CLR on the

front panel and a text message in the top center line of the display as shown in this example:

SAMPLE

A

ZERO WARNING NOX =123.4

< TST TST > CAL MSG CLR SETUP

The analyzer will also issue a message to the serial port and cause the red FAULT LED on the front panel to

blink.

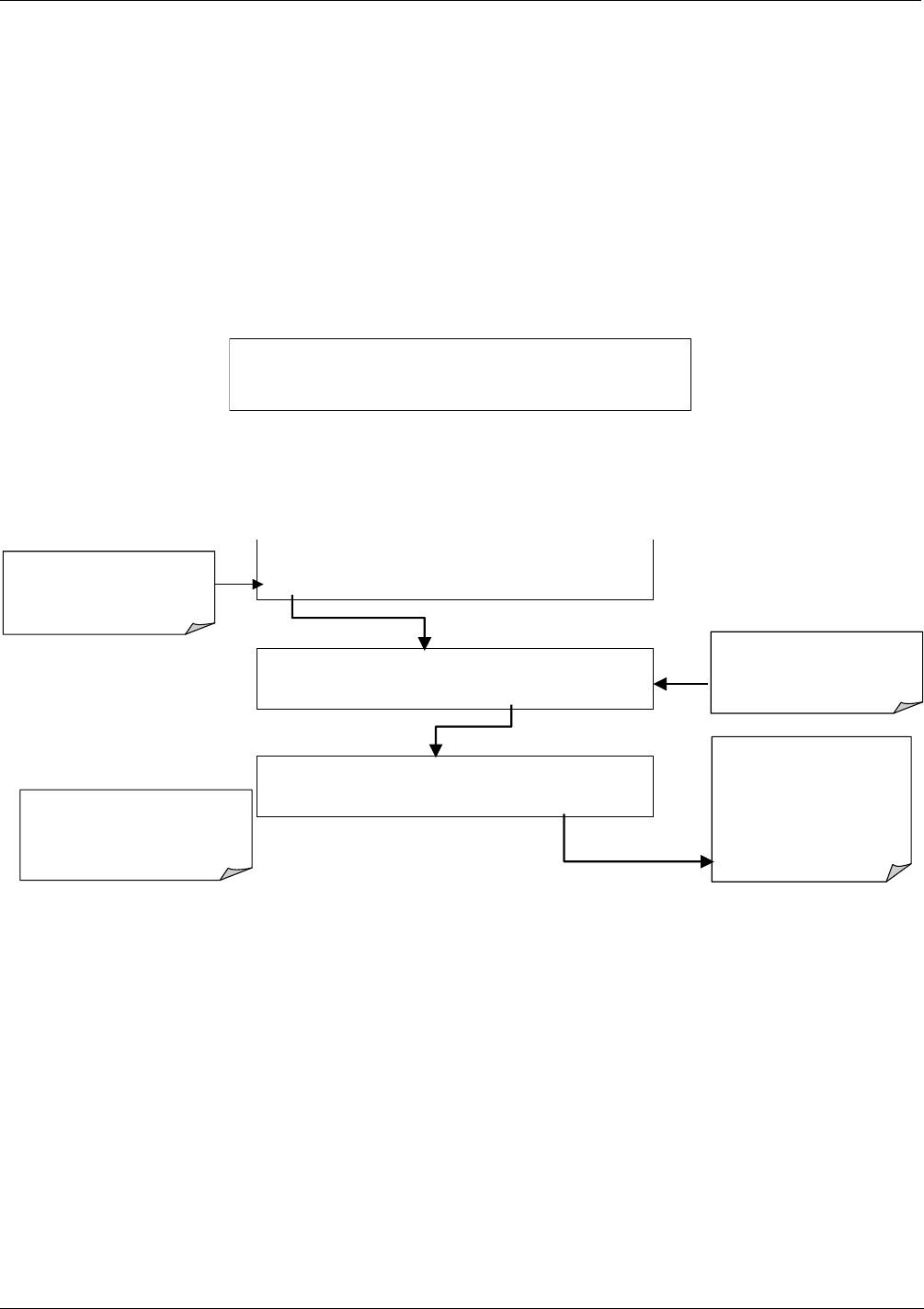

To view or clear a warning messages press:

SAMPLE SYSTEM RESET NOX = XXX.X

TEST CAL MSG CLR SETUP

If warning messages re-appear,

the cause needs to be found. Do

not repeatedly clear warnings

without corrective action.

Press

CLR

to clear the current

warning message.

If more than one warning is

active, the next message will

take its place.

Once the last warning has been

cleared, the analyzer returns to

SAMPLE Mode.

SAMPLE A1:NXCNC1=100PPM NOX=XXX.X

< TST TST > CAL MSG CLR SETUP

SAMPLE SYSTEM RESET NOX = XXX.X

< TST TST > CAL MSG CLR SETUP

<TST TST> keys replaced with

TEST key. Pressing TEST

deactivates warning messages

until new warning(s) are activated.

MSG

indicates that warning

messages are active.

All Warning messages are hidden,

but

MSG

button appears

Figure 11-1: Viewing and Clearing Warning Messages

11.1.2. FAULT DIAGNOSIS WITH TEST FUNCTIONS

Besides being useful as predictive diagnostic tools, the TEST functions, viewable from the front panel, can be

used to isolate and identify many operational problems when combined with a thorough understanding of the

analyzer’s theory of operation (Chapter 10). We recommend to use the APICOM remote control program to

download, g

raph and archive TEST data for analysis

and long-term monitoring of diagnostic data ( Section

6/15.2.8).

The acceptable ranges for these test functions are listed in Appendix A-3. The actual values for these test

functions on checkout at the factory were also listed in the Final Test and Validation Data Sheet, which was

shipped with the instrument. Values outside the acceptable ranges indicate a failure of one or more of the

analyzer’s subsystems. Functions with values that are within the acceptable range but have significantly

changed from the measurements recorded on the factory data sheet may also indicate a failure or a

04521C (DCN5731)