Teledyne API - Model 200EH/EM Operation Manual Optional Hardware and Software

45

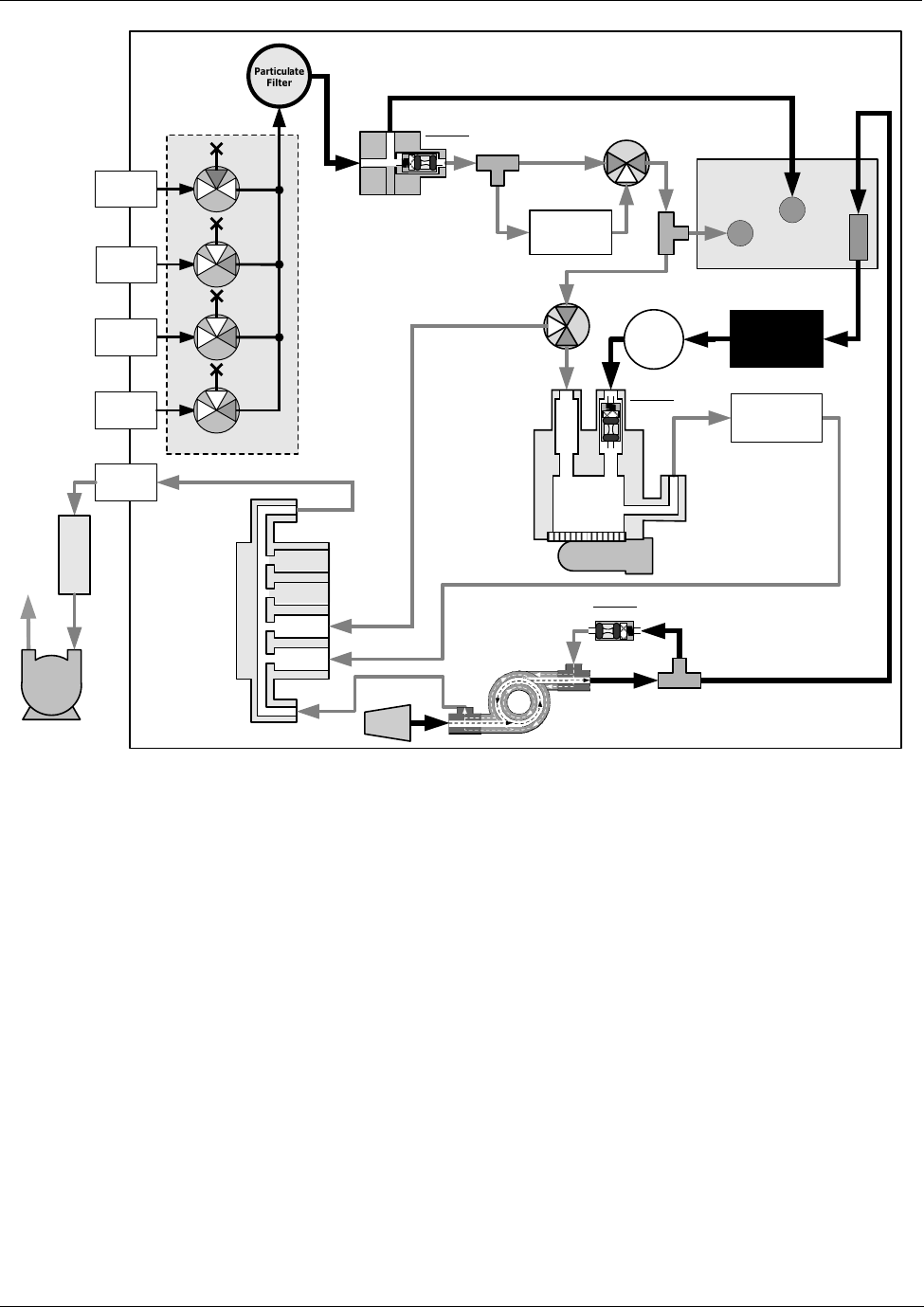

EXHAUST MANIFOLD

VACUUM

PRESSURE

SENSOR

SAMPLE

PRESSURE

SENSOR

O3 FLOW

SENSOR

FLOW PRESSURE

SENSOR PCA

INSTRUMENT CHASSIS

PMT

PERMAPURE

DRYER

NO/NO

X

VALVE

AUTOZERO

VALVE

O

3

Scrubber

O

3

GENERATOR

O

3

Purifier

EXHAUST

GAS

OUTLET

Filter

NO

2

Converter

BYPASS

MANIFOLD

REACTION

CELL

Orifice Dia.

0.003"

Orifice Dia.

0.007"

Orifice Dia.

0.004"

GAS INPUT

MANIFOLD

ZERO AIR

INLET

Zero Gas

Valve

Low Span

Valve

High Span

Valve

Span/Cal

Valve

SAMPLE

GAS

INLET

LOW

SPAN AIR

INLET

HIGH

SPAN AIR

INLET

PUMP

NO

X

Exhaust

Scrubber

Figure 5-6: M200EM – Internal Pneumatics with Second Span Point Valve Option 52

5.8. OXYGEN SENSOR (OPT 65)

5.8.1. THEORY OF OPERATION

5.8.1.1. Paramagnetic measurement of O

2

The oxygen sensor used in the M200EH/EM analyzer utilizes the fact that oxygen is attracted into strong

magnetic field, most other gases are not, to obtain fast, accurate oxygen measurements.

The sensor’s core is made up of two nitrogen filled glass spheres, which are mounted on a rotating suspension

within a magnetic field (Figure 5-7). A mirror is mounted centrally on the suspension and light is shone onto the

mirror that reflects the light onto a pair of photoc

ells. The signal generated by the photocells is passed to a

feedback loop, which outputs a current to a wire winding (in effect, a small DC electric motor) mounted on the

suspended mirror.

04521C (DCN5731)