Teledyne API - Model 200EH/EM Operation Manual Theory of Operation

197

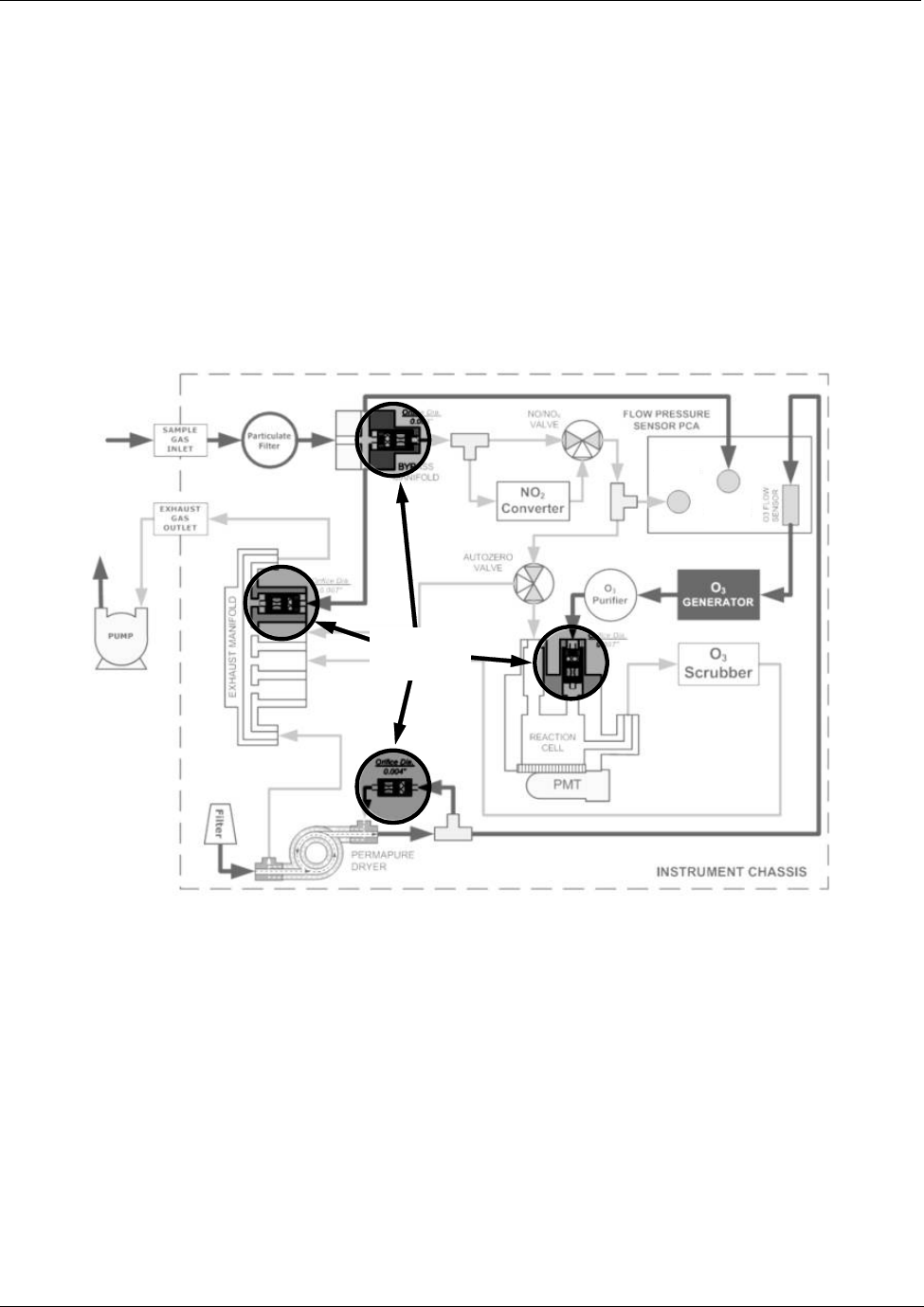

10.3.3. FLOW RATE CONTROL - CRITICAL FLOW ORIFICES

The Model M200EH/EM analyzers use special flow control assemblies located at various locations around the

instrument to maintain constant flow rates for both the O

3

supply air and the sample gas. These assemblies

consists of:

A critical flow orifice.

Two o-rings: Located just before and after the critical flow orifice, the o-rings seal the gap between the

walls of assembly housing and the critical flow orifice.

A spring: Applies mechanical force needed to form the seal between the o-rings, the critical flow orifice

and the assembly housing.

See Figures 10-6 through 10-9 For the location of these flow control assemblies:

GAS FLOW

CONTROL

ASSEMBLIES

SAMPLE

PRESSURE

SENSOR

VACUUM

PRESSURE

SENSOR

Figure 10-10-6: Location of Gas Flow Control Assemblies for M200EH

04521C (DCN5731)