Instrument Maintenance Teledyne API - Model 200EH/EM Operation Manual

178

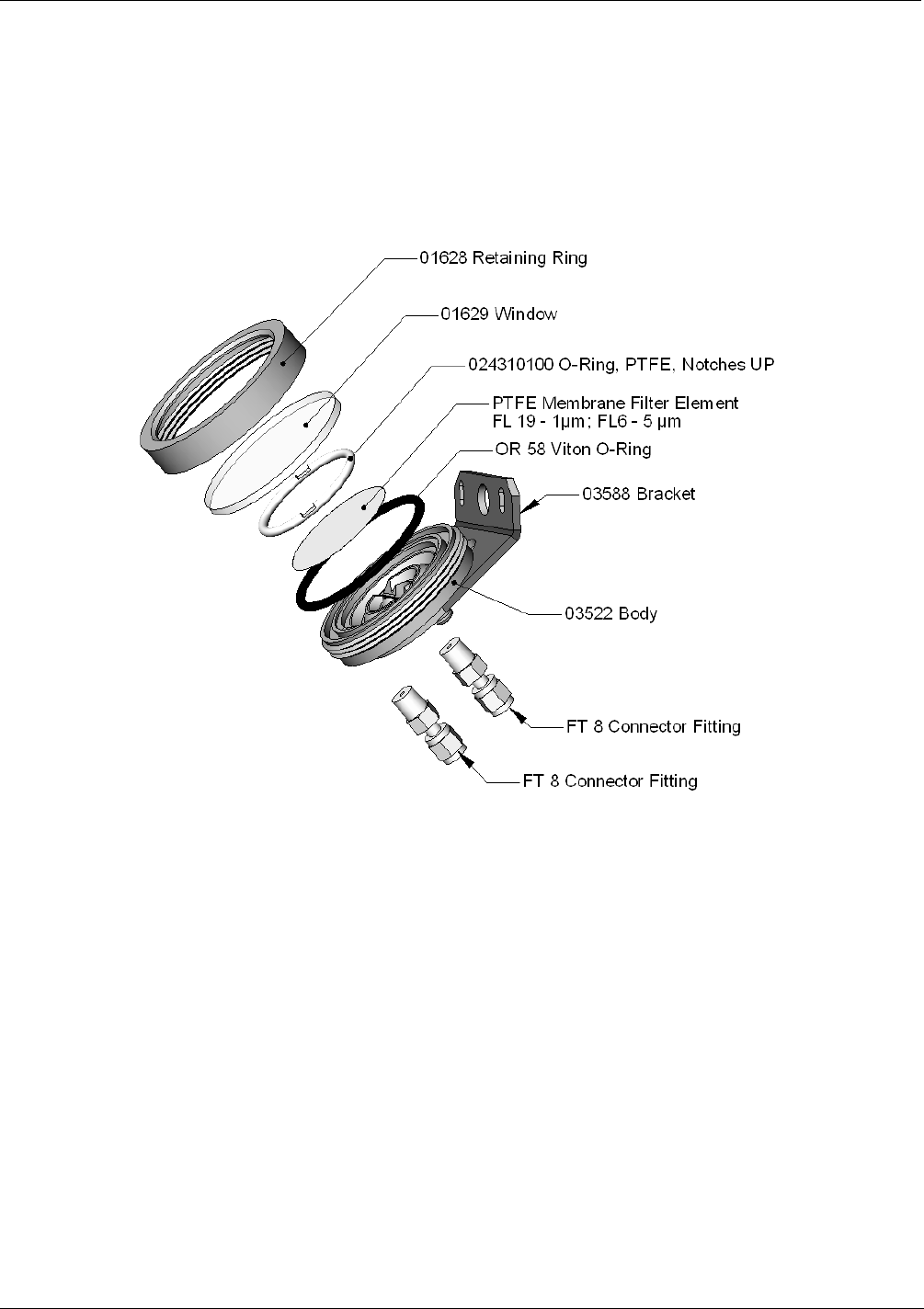

9.3.1. CHANGING THE SAMPLE PARTICULATE FILTER

The particulate filter should be inspected often for signs of plugging or excess dirt. It should be replaced

according to the service interval in Table 9-1 even without obvious signs of dirt. Filters with 1 and 5 µm pore

size can clog up while retaining a clean look. We recommend to handle the filter and the wetted surfaces of the

filter housing with gloves and tweezers. We recommend not to touch any part of the housing, filter element,

PTFE retaining ring, glass cover and the O-ring with bare hands as this may cause the pores to clog quicker and

surfa

ces to becom

e dirty due to possible oils from your hands.

Figure 9-1: Sample Particulate Filter Assembly

To change the filter according to the service interval in Table 9-1, follow this procedure:

1. Turn OFF the pump to prevent drawing debris into the sample line.

2. Remove the CE Mark locking screw in the center of the front panel and open the hinged front panel and

unscrew the knurled retaining ring of the filter assembly.

3. Carefully remove the retaining ring, glass window, PTFE O-ring and filter element. We recommend to

clea

n the glass and O-rings

at least once monthly, weekly in very polluted areas.

4. Install a new filter element, carefully centering it in the bottom of the holder.

5. Re-install the PTFE O-ring with the notches facing up (important!), the glass cover, then screw on the

hold-down ring and hand-ti

ghten the assembly. Inspect the (visible) seal between the edge of the glass

window and the O-ring to assure proper gas tightness.

6. To fulfill CE Mark safety requirements, the front panel locking screw must be installed at all times during

operation of the analyzer.

04521C (DCN5731)