Theory of Operation Teledyne API - Model 200EH/EM Operation Manual

206

10.3.10. PNEUMATIC SENSORS

NOTE

The M200EH/EM displays all pressures in inches of mercury absolute (in-Hg-A), i.e.

absolute pressure referenced against zero (a perfect vacuum).

The M200EH/EM uses three pneumatic sensors to verify gas streams. These sensors are located on a printed

circuit assembly, called the pneumatic pressure/flow sensor board, located just behind the sensor assembly.

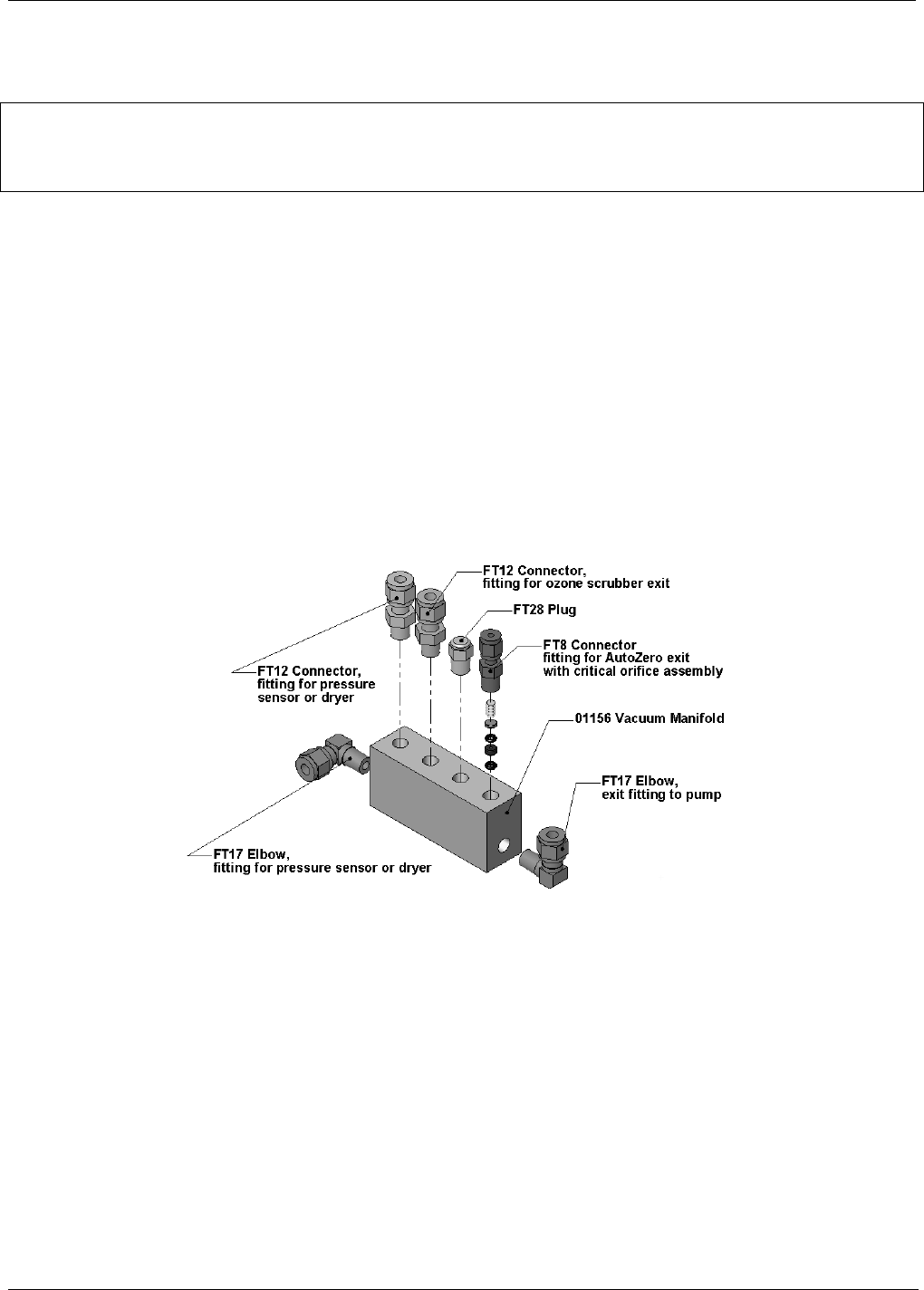

10.3.10.1. Vacuum Manifold

The vacuum manifold is the central exit port for all analyzer pneumatics. All gas streams of the analyzer exit

through this assembly and connect to the instrument’s pump. Figure 10-10-14 shows the standard

configuration. Configurations will vary depending on the option

al equipment that is installed. An IZS option, for

example, will add another FT8 connector and orifice assembly to the manifold, an optional sample dryer may

add a Tee-fitting so that two ¼” tubes can be connected to the same port.

At this time, the vacuum manifold does not yet support the orifice holder shown in Figure 9-6. To exchange the

critical orifi

ce installed in the vacuum manifold, the user nee

ds to either blow the orifice out with reversed

pressure or remove the entire manifold for this task. However, orifices installed in the vacuum manifold should

not have to be cleaned under normal circumstances.

Figure 10-10-14: Vacuum Manifold

10.3.10.2. Sample Pressure Sensor

An absolute pressure transducer connected to the input of the NO/NO

X

valve is used to measure the pressure of

the sample gas before it enters the analyzer’s reaction cell. This is the “upstream” pressure mentioned above,

which is used to compute sample flow rate. In conjunction with the vacuum pressure sensor, it is also used to

validate the critical flow condition (2:1 pressure ratio) through the sample gas critical flow orifice (Section 10.3.3).

If

the temperature/pressure compen

sation (TPC) feature is turned on (Section 10.7.3), the output of this sensor

is also used to supply pressure data for that calculation.

The act

ual pressure value is viewable through the analyzer’s front panel display as the test function

SAMP. The

flow rate of the sample gas is displayed as

SAMP FLW.

04521C (DCN5731)