Teledyne API - Model 200EH/EM Operation Manual Theory of Operation

203

10.3.7. PERMA PURE

®

DRYER

The air supplied to the O

3

generation system needs to be as dry as possible. Normal room air contains a certain

amount of water vapor, which greatly diminishes the yield of ozone produced by the ozone generator. Also,

water can react with other chemicals inside the O

3

Generator to produce chemicals that damage the optical filter

located in the reaction cell (Table 10-1) such as ammonium sulfate or highly corrosive nitric acid.

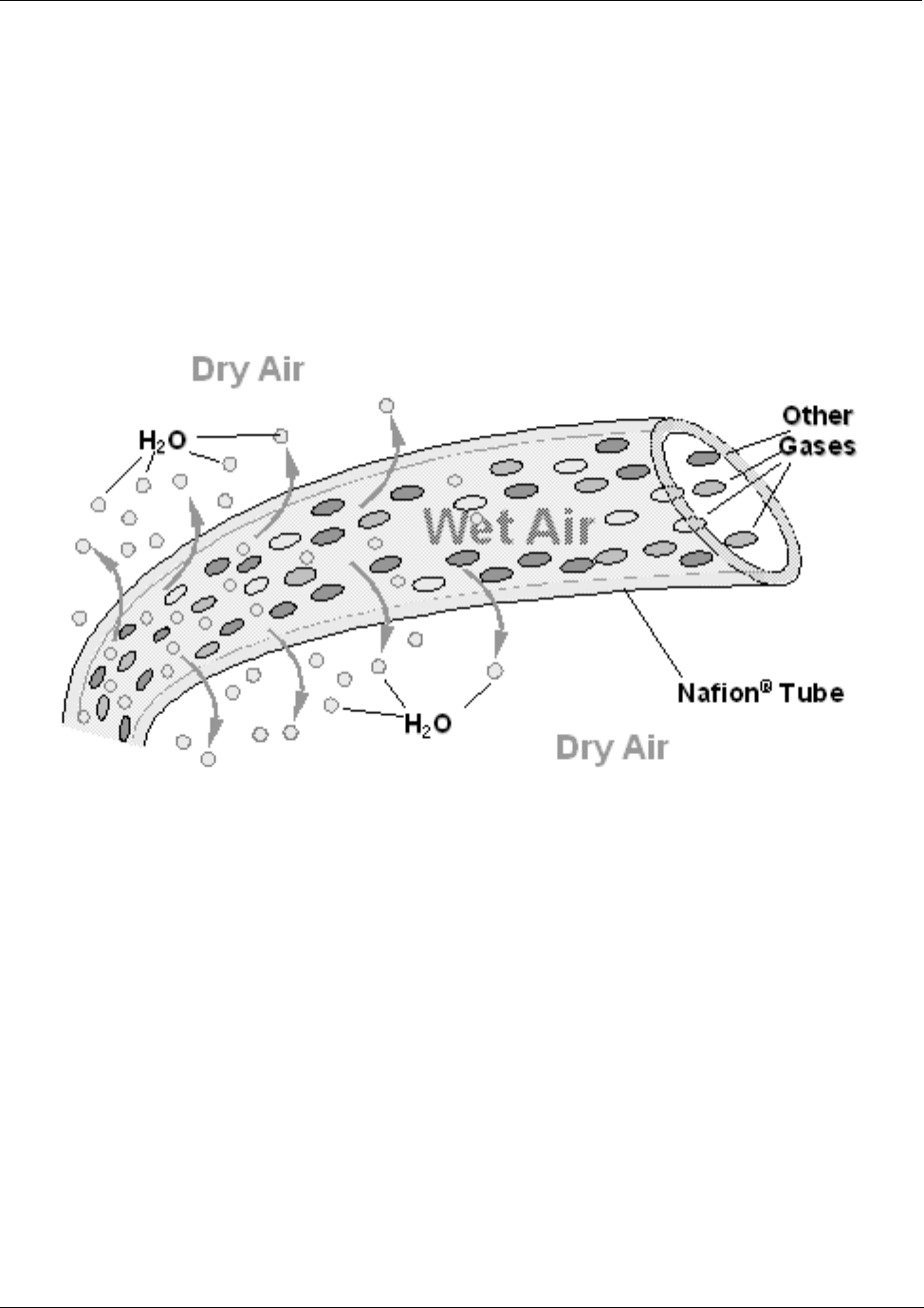

To accomplish this task the M200EH/EM uses a Perma Pure

®

single tube permeation dryer. The dryer consists

of a single tube of Nafion

®

, a co-polymer similar to Teflon

®

that absorbs water very well but not other chemicals.

The Nafion

®

tube is mounted within an outer, flexible plastic tube. As gas flows through the inner Nafion

®

tube,

water vapor is absorbed into the membrane walls. The absorbed water is transported through the membrane

wall and evaporates into the dry, purge gas flowing through the outer tube, countercurrent to the gas in the inner

tube (Figure 10-10-12).

Figure 10-10-12: Semi-Permeable Membrane Drying Process

This process is called per-evaporation and is driven by the humidity gradient between the inner and outer tubes

as well as the flow rates and pressure difference between inner and outer tubing. Unlike micro-porous

membrane permeation, which transfers water through a relatively slow diffusion process, per-evaporation is a

simple kinetic reaction. Therefore, the drying process occurs quickly, typically within milliseconds. The first step

in this process is a chemical reaction between the molecules of the Nafion

®

material and water, other chemical

components of the gases to be dried are usually unaffected. The chemical reaction is based on hydrogen bonds

between the water molecule and the Nafion material. Other small polar gases that are capable of hydrogen

bonds can be absorbed this way, too, such as ammonia (NH

3

) and some low molecular amines. The gases of

interest, NO and NO

2

, do not get absorbed and pass the dryer unaltered.

To provide a dry purge gas for the outer side of the Nafion tube, the M200EH/EM returns some of the dried air

from the inner tube to the outer tube (Figure 10-10-13). When the analyzer is first started, the humidity gradient

between the inner and outer tube

s is not very large and the dryer’s efficiency is low at first but improves as this

cycle reduces the moisture in the sample gas and settles at a minimum humidity.

04521C (DCN5731)