4 - 28

4 Servo Adjustment

MITSUBISHI CNC

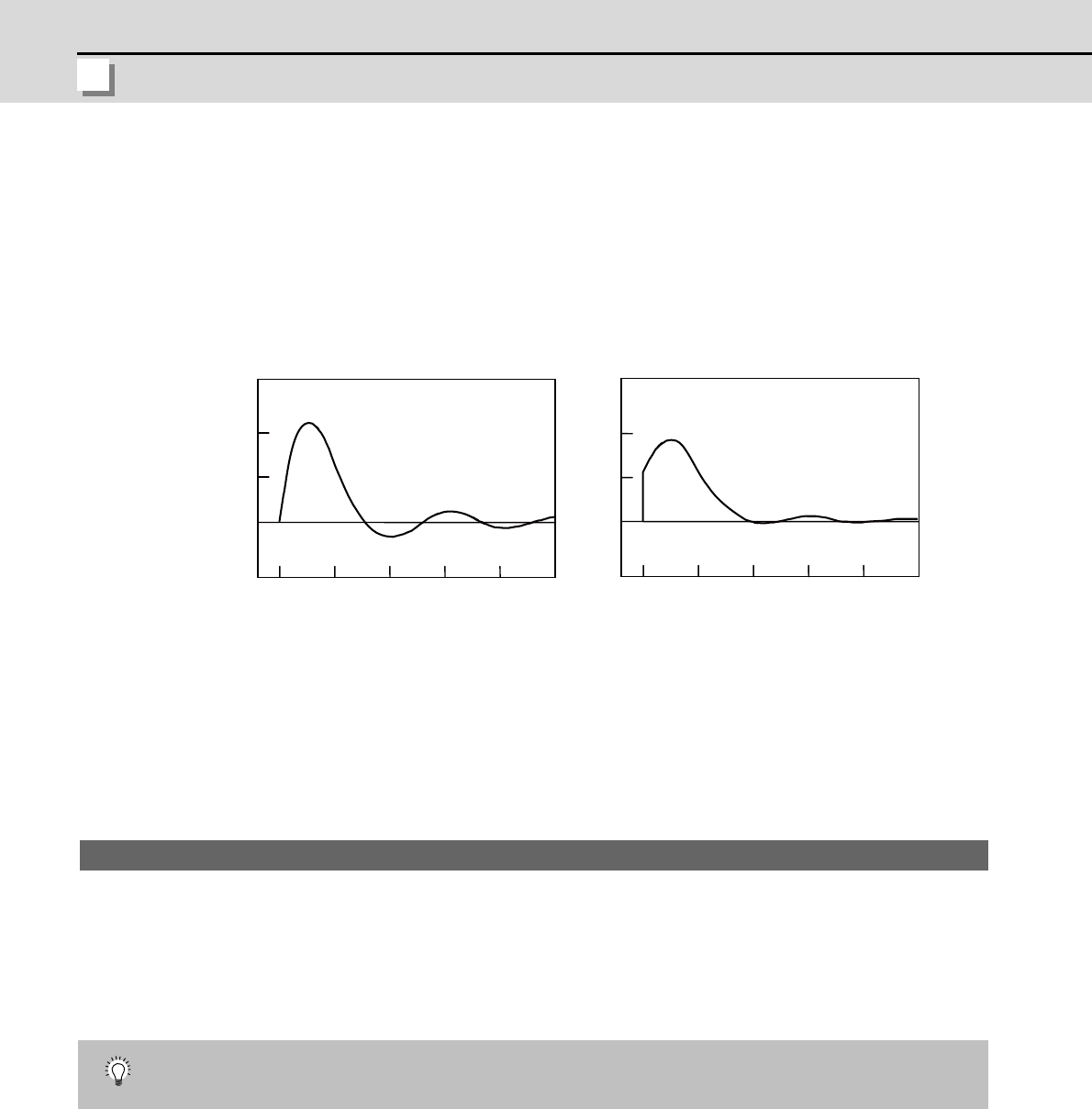

<Acceleration feed forward>

Vibration may occur at 10 to 20 Hz during acceleration/deceleration when a short time constant of 30

ms or less is applied, and a position loop gain (PGN1) higher than the general standard value or SHG

control is used. This is because the torque is insufficient when starting or when starting deceleration,

and can be resolved by setting the acceleration rate feed forward gain (SV015: FFC). This is also

effective in reducing the peak current (torque).

While measuring the current command waveform, increase FFC by 50 to 100 at a time and set the value

where vibration does not occur.

Acceleration rate feed forward gain means that the speed loop gain during acceleration/deceleration is

raised equivalently. Thus, the torque (current command) required during acceleration/deceleration

starts sooner. The synchronization precision will improve if the FFC of the delayed side axis is raised

between axes for which high-precision synchronous control (such as synchronous tapping control and

superimposition control).

【#2215】 SV015 FFC Acceleration rate feed forward gain

When a relative error in synchronous control is too large, set this parameter to the axis that is

delaying.

The standard setting is "0". The standard setting in the SHG control is "50".

To adjust a relative error in acceleration/deceleration, increase the value by 50 - 100 at a time.

---Setting range---

0 to 999 (%)

Overshooting occurs easily when a value above the standard value is set during SHG control.

Current

command

(%)

200

100

0

100

806040

200

Time

(

ms

)

200

100

0

100

806040

200

Time

(

ms

)

No FFC setting

With FFC setting

POINT