5 - 18

5 Spindle Adjustment

MITSUBISHI CNC

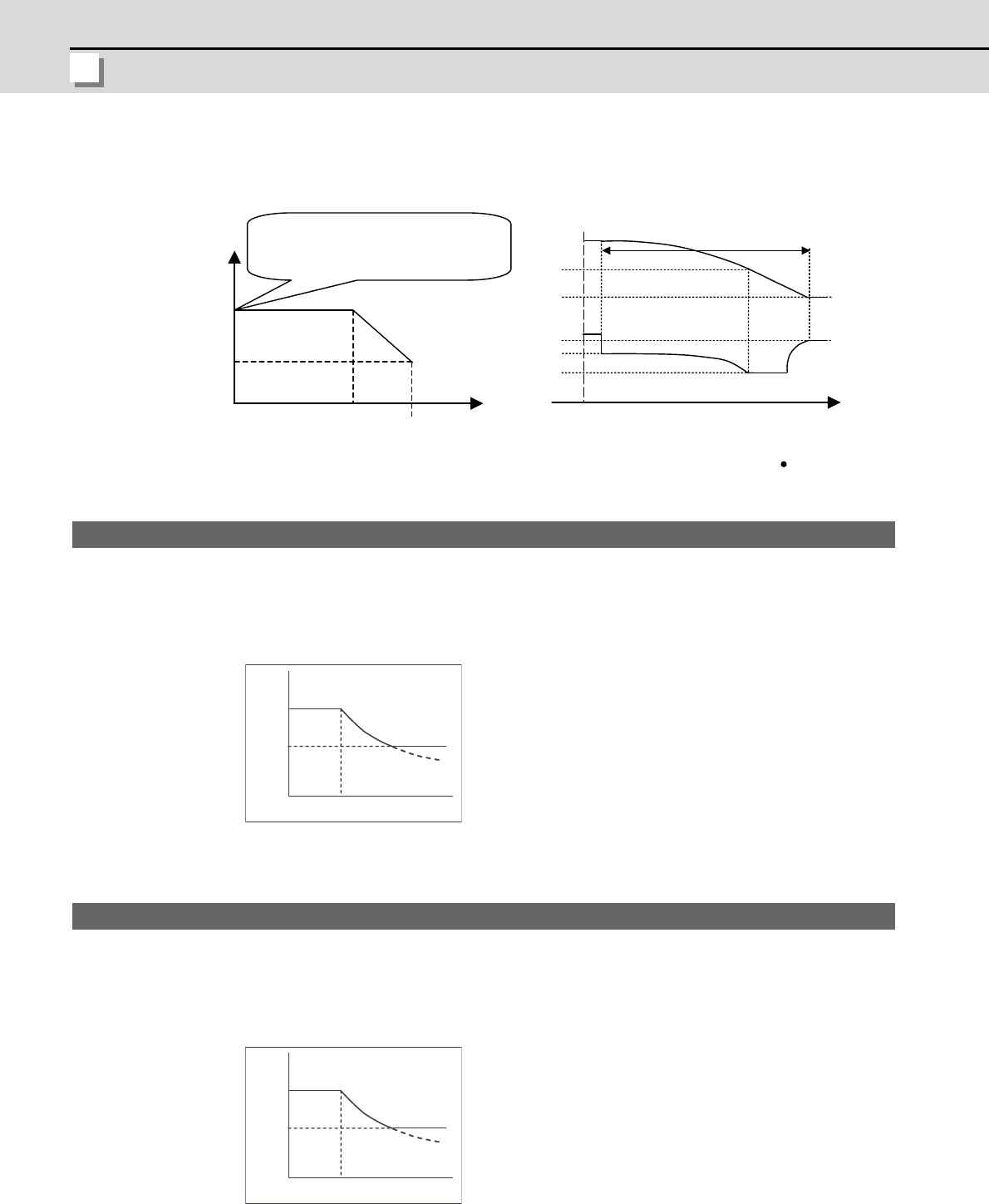

Relation between SP071 (variable current limit during deceleration, lower limit value) and

SP072 (variable current limit during deceleration, break point speed)

【#13071】 SP071 DIQM Variable current limit during deceleration, lower limit value

Set this parameter to adjust the deceleration time by changing the current limit value during

deceleration depending on the motor speed.

As shown below, set the lower limit rate of the current limit in SP071 (DIQM), and use with SP072

(DIQN).

When DIQM is set to 100%, the current limit value in deceleration (TMRL) set in the motor constants

is applied.

---Setting range---

0 to 999 (%)

【#13072】 SP072 DIQN Variable current limit during deceleration, break point speed

Set this parameter to adjust the deceleration time by changing the current limit value during

deceleration depending on the motor speed.

As shown below, set the lower limit rate of the current limit in SP071 (DIQM), and use with SP072

(DIQN).

When DIQM is set to 100%, the current limit value in deceleration (TMRL) set in the motor constants

is applied.

---Setting range---

1 to 32767 (r/min)

100

SP072

SP071

0

0

<1>

<2>

SP072

SP026

<1> SP152(SP184)×SP071/100

<2> SP152(SP184)

0

Current limit

Motor rotation speed

Max. rotation speed

Decreasing current value

”100” is the setting value for the current limit

during regeneration (SP152 (high-speed coil),

SP184 (low speed coil)).

(1) Rotation speed – Decreasing current value curve

Time

(

s

)

Motor rotation speed

Deceleration time

q axis command/FB

(2) Rotation speed/current command FB waveform

DIQN

0

DIQM

100%

(TMLR)

Motor speed

DIQN

0

DIQM

100%

(TMLR)

Motor speed