6 - 15

MDS-D-SVJ3/SPJ3 Series Instruction Manual

6-3 Troubleshooting

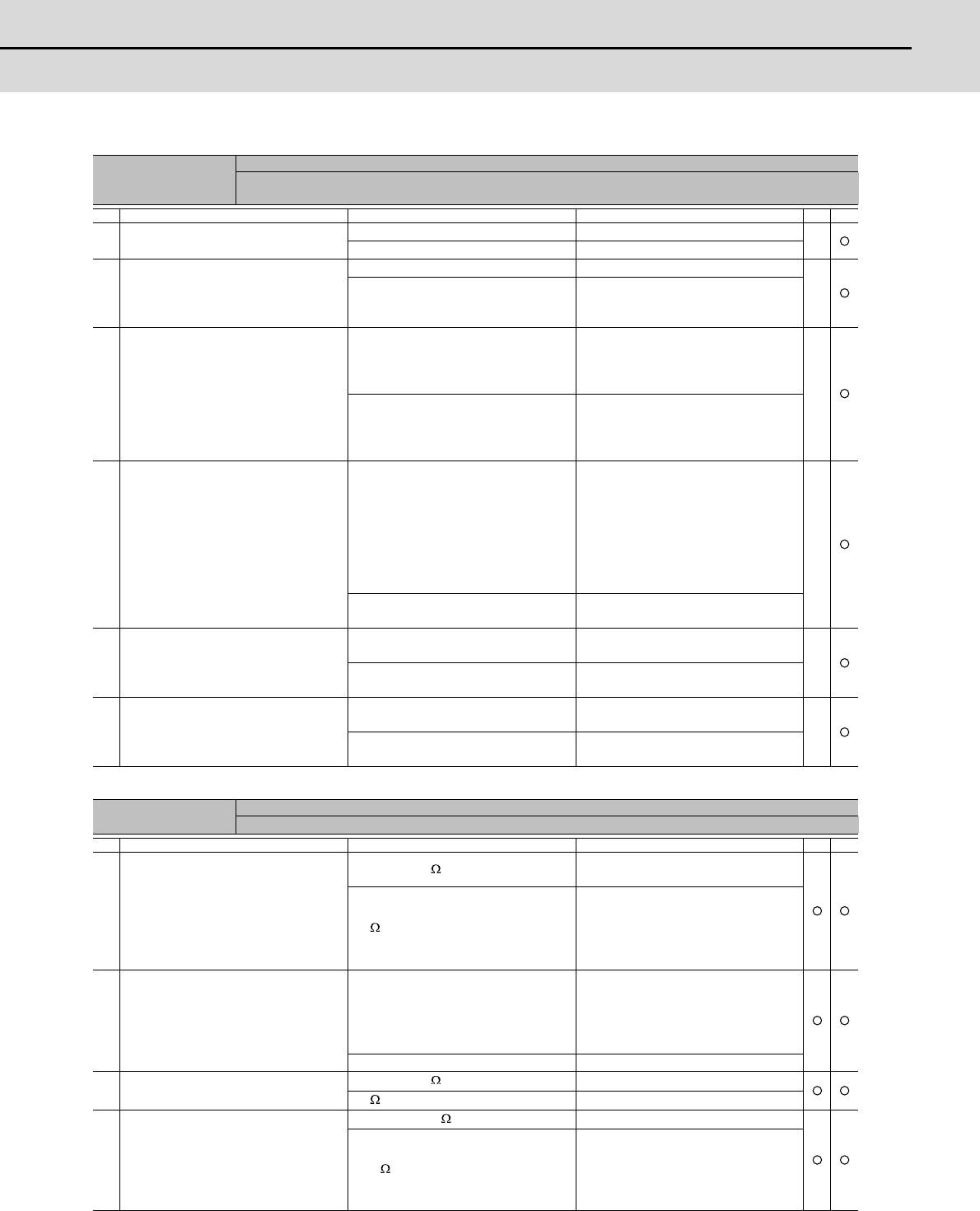

Alarm No.

23

Excessive speed error

A difference between the speed command and speed feedback was continuously exceeding 50 r/min for

longer than the setting time.

Investigation details Investigation results Remedies SV SP

1

Check the U, V and W wiring connect-

ed to the spindle drive unit.

The wires are not correctly connected. Correctly connect.

The wires are correctly connected. Check the investigation item No. 2.

2

Check the spindle parameter SP020,

SP026, SP027, from SP057 to SP064

and spindle specification parameters

from slimit1 to slimit4 setting value.

The correct values are not set. Correctly set.

The correct values are set. Check the investigation item No. 3.

3

Measure the acceleration/ decelera-

tion time from 0 to the point where the

spindle speed reaches its maximum.

If the alarm occurs when forward run is

changed to reverse run, measure the

acceleration/ deceleration time from

the forward to reverse. Also measure it

from the reverse to forward.

12sec or more.

(SP117 setting value or more.)

Increase the spindle acceleration/de-

celeration time constant setting val-

ue(sp_t1 to sp_t4).

Reduce the load inertia.

Less than 12sec. Check the investigation item No. 4.

4

Check the load amount when the

alarm occurred during cutting.

The speed deterioration due to load

amount has exceeded the tolerable

range which is determined by the pa-

rameter SP096.

-If SP096 is set to 0, it is regarded as

85%. Thus a speed of 85% of the ma-

chining speed or faster will be the tol-

erable speed.

Reduce the cutting load to mitigate the

speed deterioration.

Replace the tool.

The load amount is within the SP096

setting value.

Check the investigation item No. 5.

5

Check the fluctuation of the input volt-

age into the power supply unit with a

tester.

Voltage drop during acceleration is

200V or less

Review the power supply capacity.

Voltage drop during acceleration is

200V or more

Check the investigation item No.6.

6 Check the capacity of the drive unit.

The capacity does not satisfy the mo-

tor output.

Change the capacity to the selected

one.

The capacity satisfies the motor out-

put.

Replace the unit.

Alarm No.

24

Grounding

The motor power cable is in contact with FG (Frame Ground).

Investigation details Investigation results Remedies SV SP

1

Measure the insulation across the

power cables (U,V,W) for connected

motors and the ground. (Carry out a

megger test.)

(Note)

When the insulation is measured, dis-

connect wires from the drive unit.

Less than 1M .

The motor or power cable may be

ground faulted.

1M or more.

Check the investigation item No. 2.

2

Has oil come in contact with the motor

or power cable?

Oil has come in contact.

Take measures so that oil does not

come in contact. Check the motor's

cannon connector and the inside of

the terminal box, and clean as neces-

sary.

Oil has not come in contact. Check the investigation item No. 3.

3 Measure the insulation again.

Less than 1M .

Replace the motor or cable.

1M or more.

Check the investigation item No. 4.

4

Measure the resistance across the U,

V, W phase terminals of the servo/

spindle drive unit and the ground with

a tester.

(Note) Do not measure the insulation

as the unit is damaged.

Less than 100k .

Replace the drive unit.

100k or more.

Replace the power supply unit.