1 - 27

MDS-D-SVJ3/SPJ3 Series Instruction Manual

1-5 Installation of the spindle detector

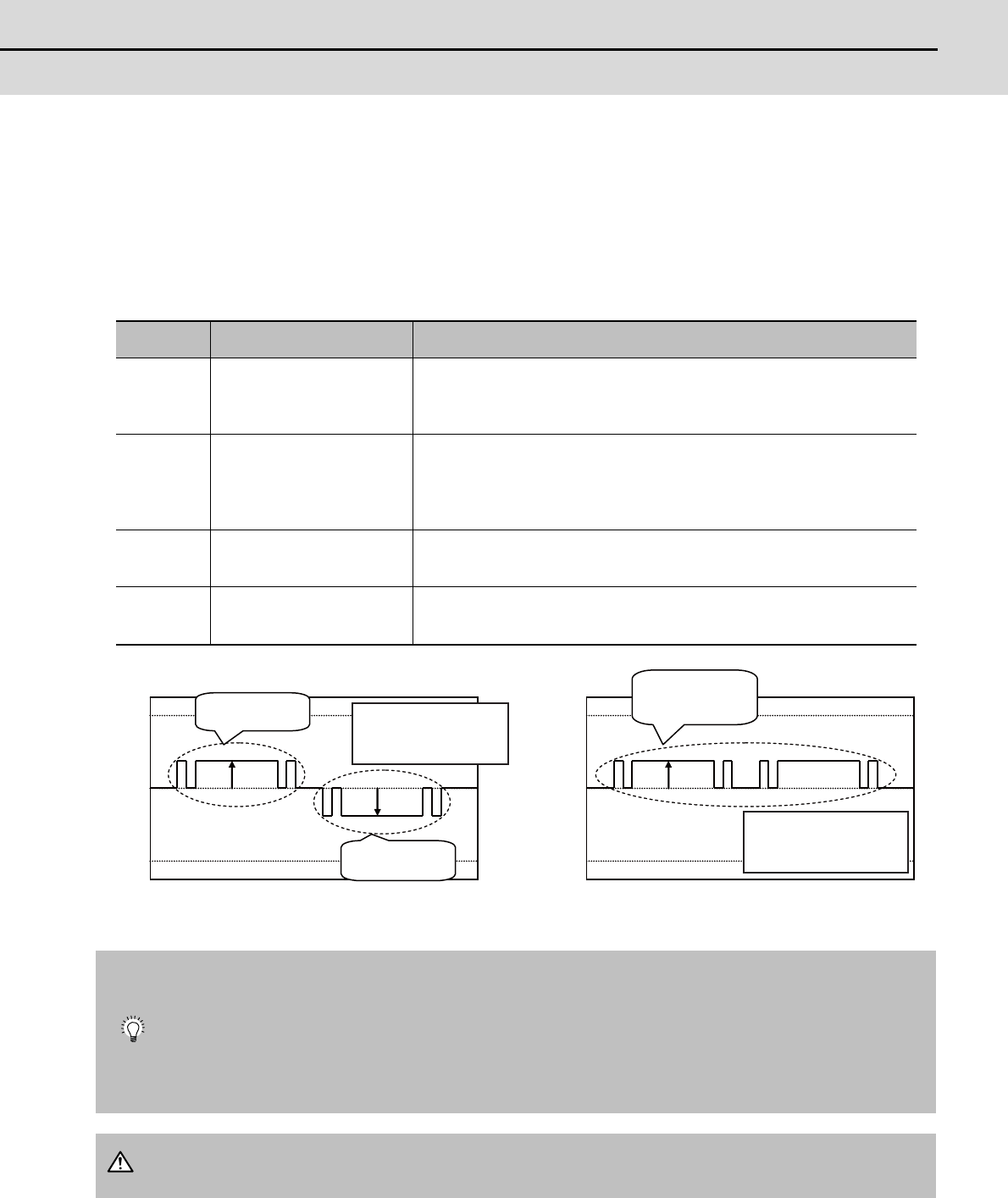

(3) Details for PLG installation diagnosis

Installation error judgment of the adjustment-free PLG can be checked using the D/A output of the

spindle drive unit. The setting numbers of D/A output are shown below. For the output waveform, 2.5V

represents a normal state and +1V or -1V of the normal state represents an abnormal state.

*Set the D/A output numbers to the spindle parameters "#13125(SP125)" and "#13126(SP126)".

Because the D/A output of the drive unit is 2ch, perform the check for both at the motor end and spindle

end in full closed mode.

(4) Related alarms

There is no alarm related to the installation accuracy diagnosis for PLG detector.

D/A output

No.

Details Description

120

Motor end PLG installation

Gap diagnosis

The result of the quality judgement for the gap of the motor end PLG is

output.

When the gap is good, =2.5V is output. When the gap is excessive,

=2.5+1V is output and when the gap is too small, =2.5-1V is output.

121

Motor end PLG installation

All errors diagnosis

The result of the quality judgement for the installed position of the motor

end PLG is output.

When the sensor installation is good, =2.5V is output. When sensor instal-

lation is incorrect (such as a center deviation between a sensor and gear,

and Z-phase error), =2.5+1V is output.

122

Spindle end PLG installation

Gap diagnosis

The result of the quality judgement for the gap of the spindle end PLG is

output.

The output procedure is the same as that of motor end PLG.

123

Spindle end PLG installation

All errors diagnosis

The result of the quality judgement for the installed position of the spindle

end PLG is output.

The output procedure is the same as that of motor end PLG.

When the D/A output parameter "#13125(SP125)" is set to 120(=D/A output of ch1), and

"#13126(SP126)" is set to 121(=D/A output of ch2), the check is performed at the motor end detector.

When the D/A output of ch1 is 2.5V and ch2 is 3.5V(=2.5+1V), for example, the gap is normal,

however, the center deviation (offset) between a sensor and gear occurs, so check again after the

sensor installed position is finely adjusted. Adjust until the two D/A outputs finally become 2.5V during

spindle rotation.

When the sensor installed position is finely adjusted, adjust after the power of the drive unit is turned

OFF.

5.0V

2.5V

0.0V

5.0V

2.5V

0.0V

+1V

-1V

+1V

The gap is excessive

Waveform example

when the gap is not good

The gap is too small

Waveform example

when all results of the diagnosis are not good

Offset fault

Gap fault

Z-phase error

The gap is good when the

waveform is constantly at

2.5V during the rotation.

The installation is good when

the waveform is constantly at

2.5V during the rotation.

POINT

CAUTION