5 - 10

5 Spindle Adjustment

MITSUBISHI CNC

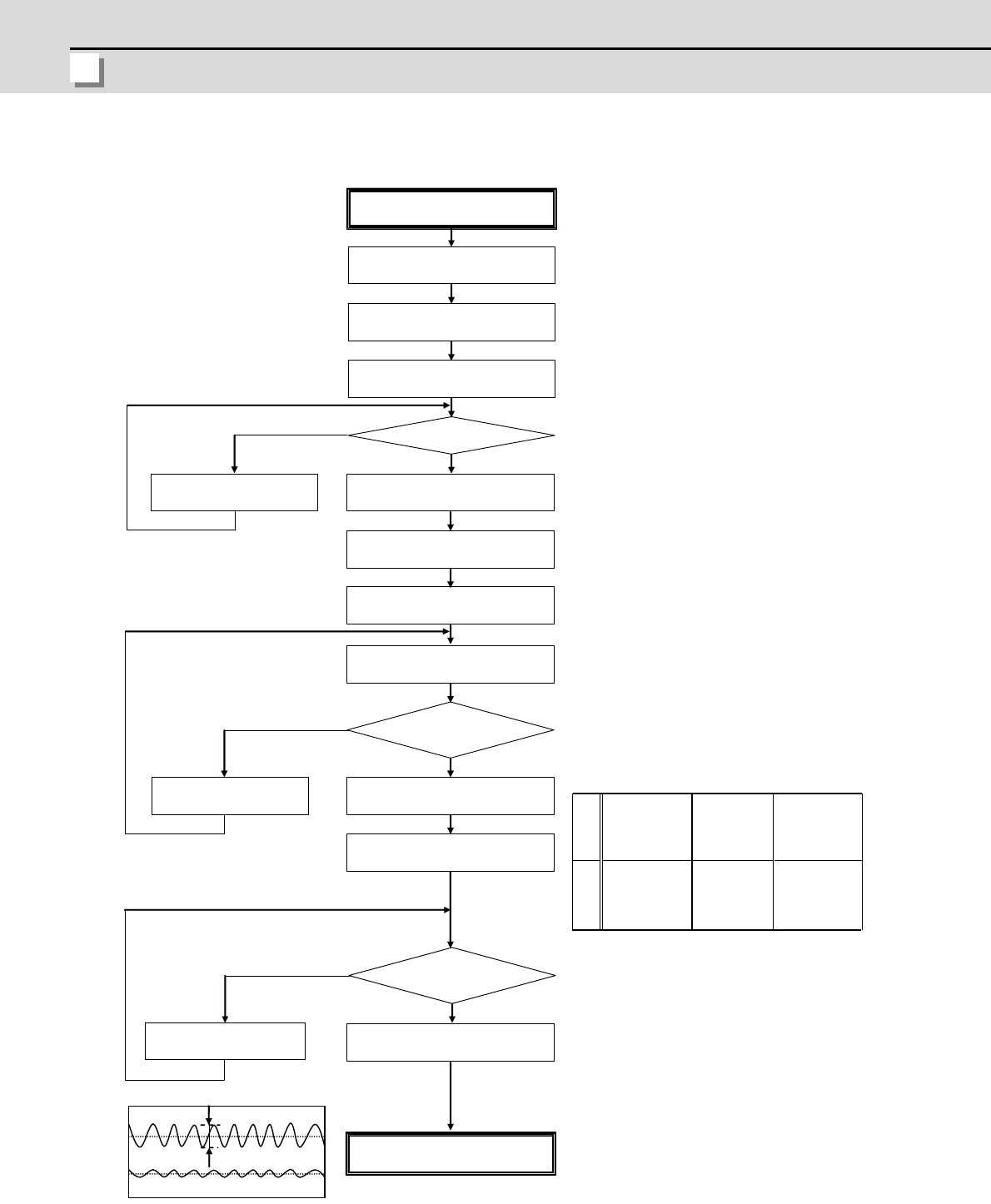

(3) Adjusting the speed loop parameter

Stops at servo ON status

Increase the value up to where

resonance occurs.

Set SP005 (standard setting 150)

Command M19 (orientation stop)

Adjust speed loop gain

Set SP001=15

Resonance occurs?

Increase SP005 by +20

Emergency stop

Command M19 (orientation stop)

Increase SP005 by -20

Subtract 20 from SP005

Acceleration/deceleration

operation

Resonance

(abnormal noise) or abnormal

operation occurs?

Command M19 (orientation stop)

Set D/A output as shown

on the right.

Waveform

for Ref.

0.045

°

or less

q

axis current command

Position droo

p

Adjustment completed

Multiply SP005 by 0.9

Subtract 3 from SP005

Is droop oscillation

0.045°p-p or less?

Note that the maximum setting value is as follows:

SP005(max)150 x inertia ratio

(Inertia ratio total inertia/motor inertia

(Example)

When inertia rate is double and the determined gain is

350, the setting value for SP005 is 315, which is 90%

of the determined gain, however,the setting value for

SP005 should be 300, because the maximum setting

value is 150x2(inertia rate)=300.

Output

waveform

Position

droop

Output

waveform

q axis current

command

Executes acceleration/deceleration operation in phase

up to maximum rotation speed from 0.

(Note)

hen the maximum speed is 10000r/min, executes in

approx. 1000r/min increments, divided by 10.

SP125 60

SP126 2

SP127 4000

(0.025°/V)

SP128:1000

(10%/V)

Ch1

Ch2

Yes

NO

YES

NO

0

0

NO

YES