4 - 30

4 Servo Adjustment

MITSUBISHI CNC

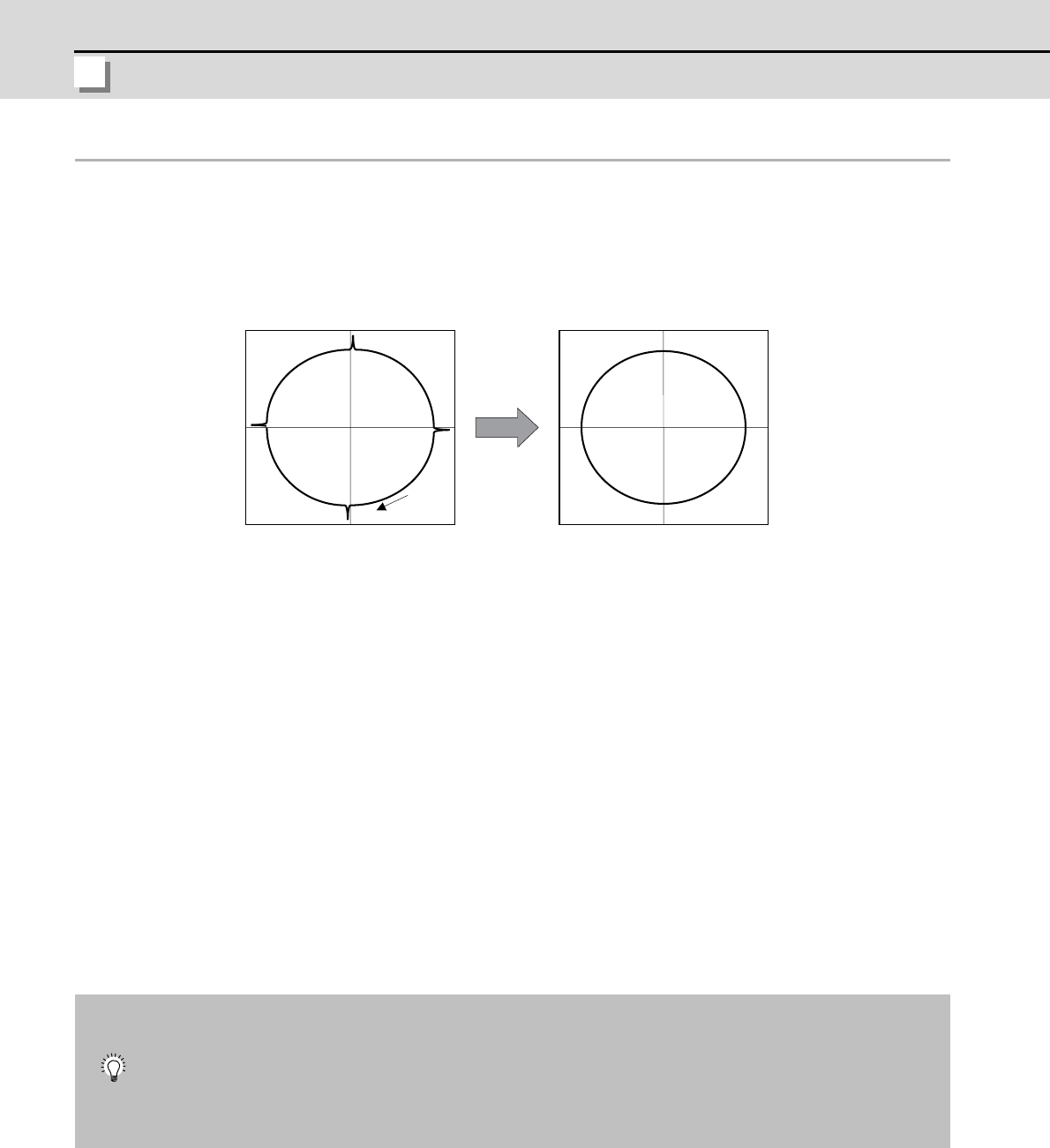

4-4-5 Improvement of protrusion at quadrant changeover

The response delay (caused by dead band from friction, torsion, expansion/contraction, backlash, etc.)

caused when the machine advance direction reverses is compensated with the lost motion compensation

(LMC compensation) function.

With this, the protrusions that occur at the quadrant changeover in the DBB measurement method, or the

streaks that occur when the quadrant changes during circular cutting can be improved.

DBB: Double Ball Bar

[1] LMC compensation type 2

This is an obsolete compensation method. When performing new adjustment, use LMC compensation

type 3.

[2] LMC compensation type 3

In addition to frictional torque influence, this type compensates torsion and expansion/contraction

influences in the machine system in which compensation amount is changed by travel speed. A

mechanical system viscosity coefficient setting further enhances the compensation accuracy even if the

travel speed is changed. Adjustment requires a machine roundness measurement.

[3] LMC compensation type 4

This is used in combination with LMC compensation type 3. Compensation is performed by monitoring

path tracking delay. Therefore, even if the machine friction amount has changed due to aged

deterioration, the path tracking delay is controlled so that it will be minimum.

1. LMC compensation performs adjustment while measuring the electrical end roundness waveform

(detector position FB). Disable the NC side machine error compensation (pitch error

compensation, relative position compensation, backlash compensation).

2. After the compensation adjustment is completed, adjust the machine error compensation while

measuring the machine error compensation with DBB measurement method, etc.

Com

p

ensation

Cutting

d

ir

ec

ti

o

n

Circle cuttin

g

p

ath after com

p

ensation

Circle cutting path before compensation

POINT