Appendix 2 - 7

MDS-D-SVJ3/SPJ3 Series Instruction Manual

Appendix 2-1 CM10-SPxxS-x(D6) plug connector

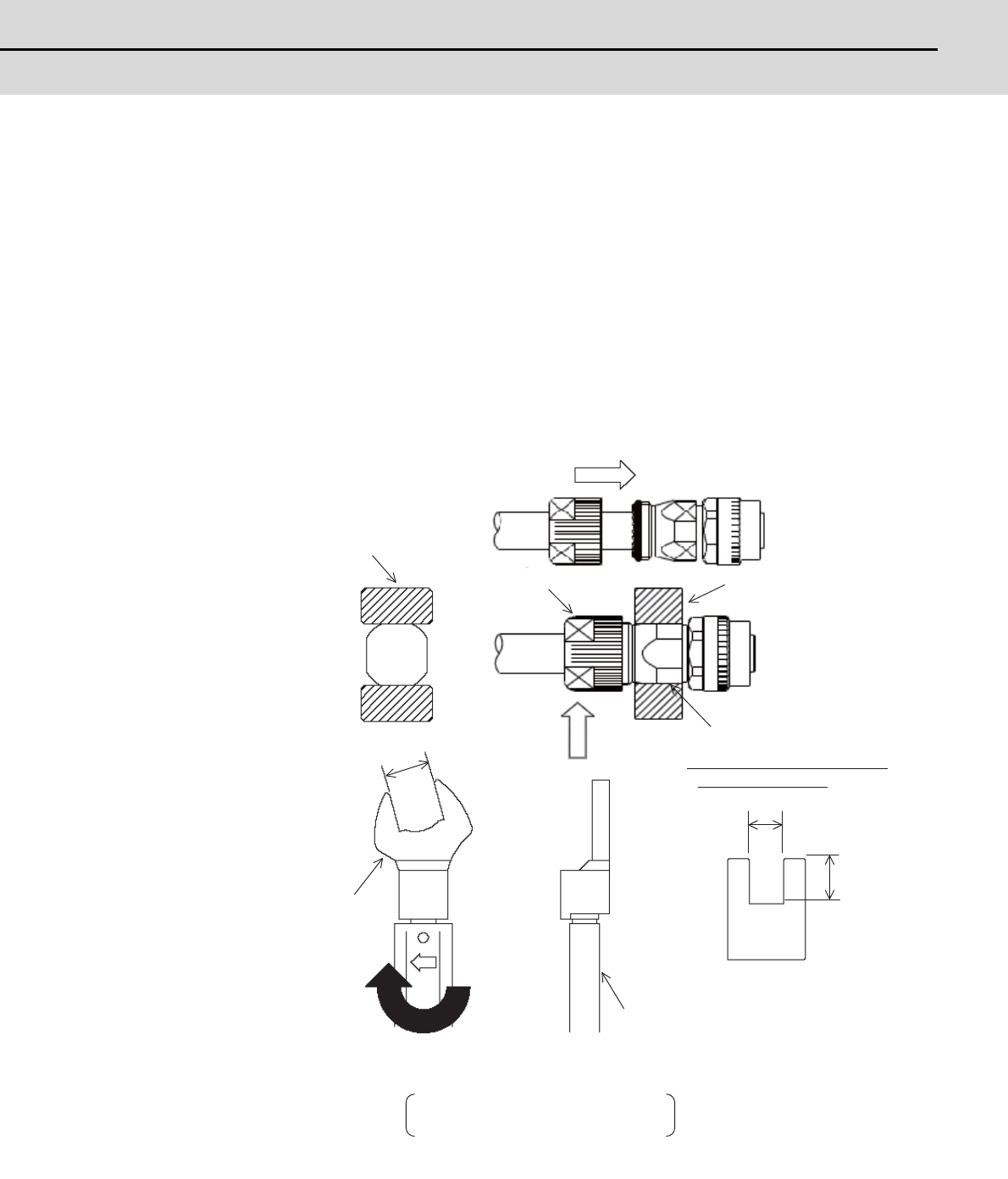

(8) Tightening a clamp nut

[1] Temporarily tighten the clamp nut on the angle back shell.

*To prevent the loosening, it is recommended to coat the straight back shell with adhesive.

Recommended adhesive: 1401B (Three Bond Co., Ltd.)

[2] Fix the 2 surface width of the angle back shell on the tightening guide.

[3] Set the tightening wrench adjusting the 2 surface width of the clamp nut.

[4] With the wrench, tighten the clamp nut on the angle back shell.

Recommended tightening torque: 5N•m

(Note 1) When setting the work to the wrench, adjust the 2 surface width.

In case of squeezing the clamp nut with excessed torque provided as above, the clamp

nut may be broken. Please use the torque wrench.

To remove, take the reverse steps.

19

17

20

* Recommendation

Adhesive (2 threads around

the circumference)

Temporary tightening

Tightening guide

Clamp nut

Tightening guide

Back shell

Set

Clamp nut

wrench

Tighten

Torque wrench

(Back shell width)

Thickness

:10

* Recommendation :

Tightening guide

(357J-50494T)

* Referential dimensions for back

shell tightening guide

٨Recommended jigs and tools : Clamp nut wrench(357J-51334T)

Bit (357J-51345T)

Torque wrench (CL6N x 8D, Tonichi Mfg.)

* Recommended tightening jig : (357J-50494T)