Appendix 3 Precautions in Installing Spindle Motor

MITSUBISHI CNC

Appendix 3 - 4

Appendix 3-4 Precautions in coupling shafts

(1) When direct coupling between the motor shaft and spindle shaft is not accurate, abnormal vibration and/

or sound may result. Therefore, do not rely too much on the coupling's flexibility but perform centering

and parallel correcting carefully during shaft coupling.

(2) According to the motor specifications, the allowable load on the motor shaft in the motor's inward

direction (thrust direction) is 0 [kgf]. Thus you have to choose a coupling that causes no thrust load on

the motor shaft, and also pay attention to the extension by thermal expansion.

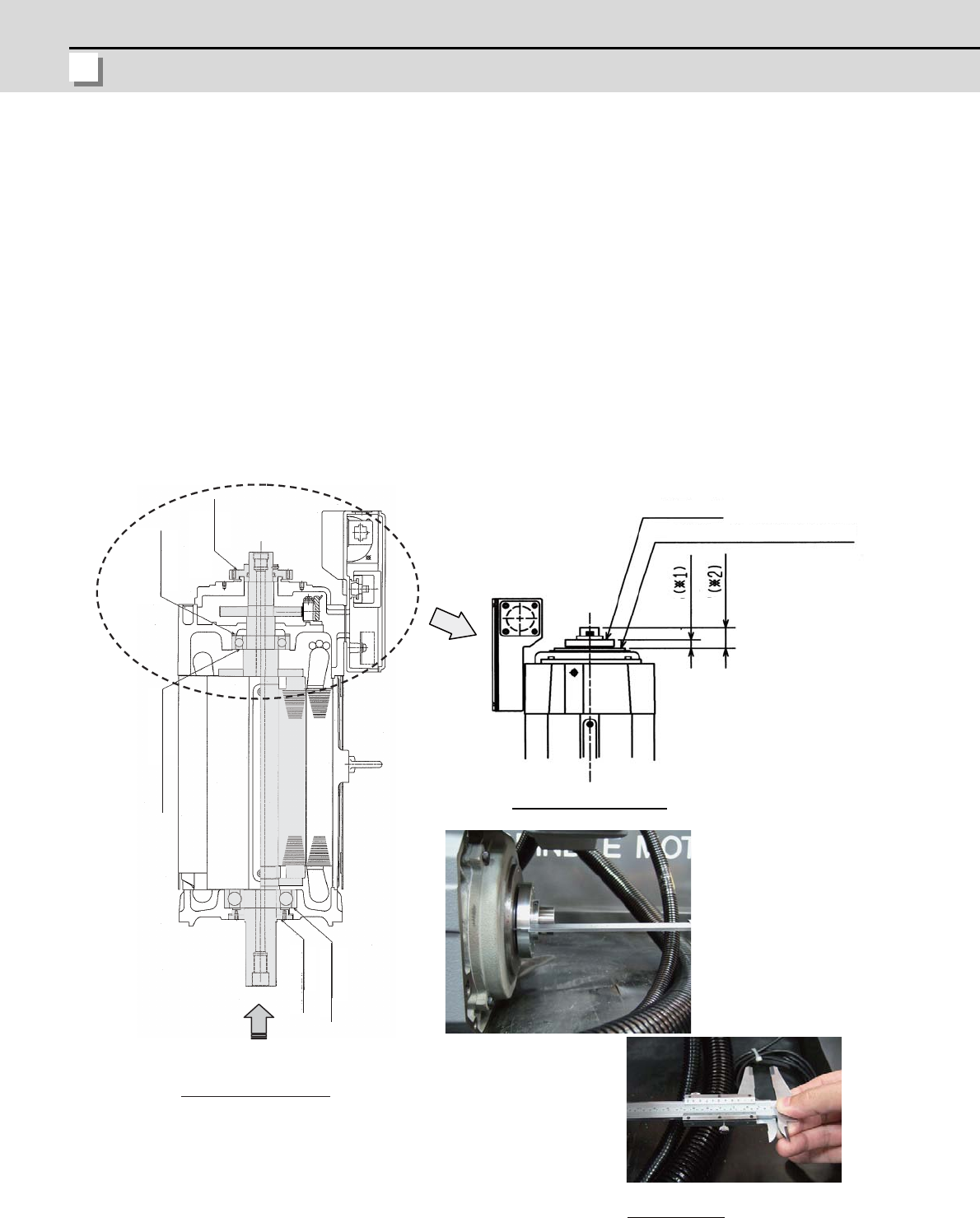

(3) If a gear coupling or Oldham coupling is used, the motor shaft may be kept pushed into the motor's

inward when the shaft is inserted into the spindle head. For a hollow-shaft specification, measure the

distance A or B before and after insertion to confirm that there is no difference between before and after

insertion (the allowance is ±0.1mm)

- Distance A: between the rotary joint fitting attachment surface and the rotation seal's end face (*1)

- Distance B: between the rotary joint fitting attachment surface and the opposite load side shaft end (*2)

B

A

Rotation seal

Bearing

pre-load spring

Opposite load side Bearing

Load side Bearing

Rotation seal

Rotation seal

Rotary joint fitting attachment surface

Enlarged view of motor rear

Motor structural drawing

Thrust load

How to measure