5 - 20

5 Spindle Adjustment

MITSUBISHI CNC

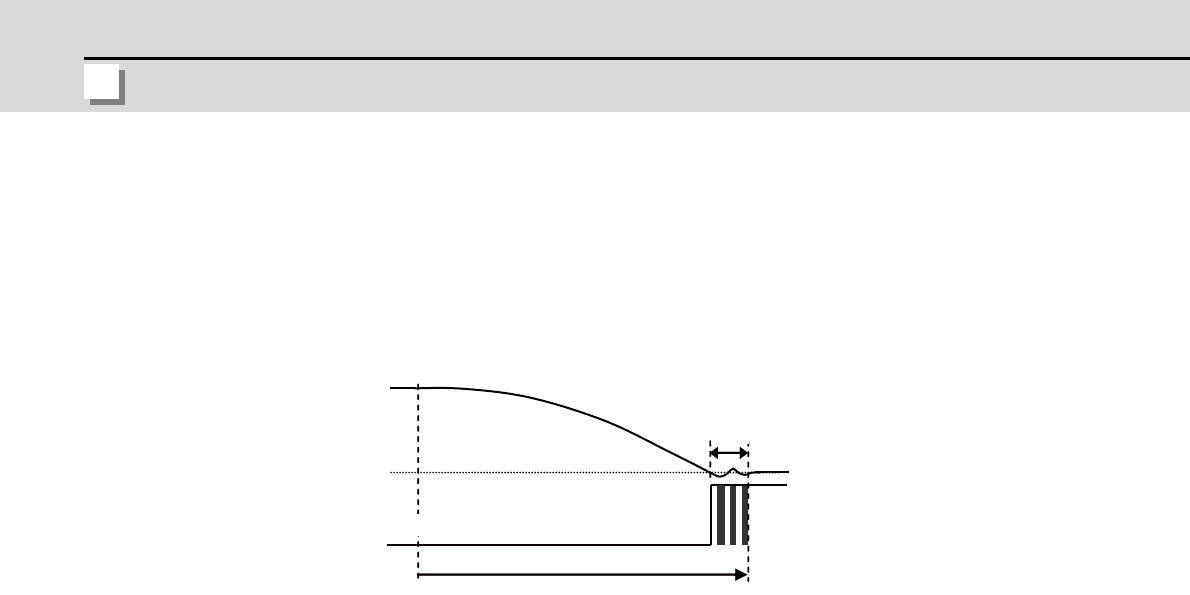

(2) Confirmation in orientation stop at deceleration ?0 rotation according to spindle specification

If orientation stop is performed with the load inertia increased due to an excessive workpiece or tool

installed to the spindle, the spindle may start vibrating by trying to reverse after overshooting the stop

position and stop after converging the vibrations (refer to the waveform below).

In this case, the orientation completion time is extended by the time to converge the spindle vibrations.

Thus, the adjustment to suppress the reversing and vibrations at stop is required.

<Adjustment method>

(1) Set SP016: Lower the setting value by 5. By lowering, the inclination of the speed becomes

gradual. Set the optimum value while observing the speed waveform so that the speed will not

vibrate.

(2) Lower the position loop gain.

By lowering the position loop gain, a sway that exceeds the stop position is suppressed.

(3) Adjust the speed gain (SP005, SP006).

The converging time becomes shorter if the rigidity during orientation stop is higher. However this

affects the speed stability during constant feed, thus it is required to confirm the speed waveform at

the constant speed and the machining surface during cutting.

Vibration

Motor rotation speed

In-position signal