6 - 31

MDS-D-SVJ3/SPJ3 Series Instruction Manual

6-3 Troubleshooting

Alarm No.

53

Excessive error 2

A difference between the actual and theoretical motor positions during servo OFF exceeded the setting val-

ue.

Investigation details Investigation results Remedies SV SP

1

Check the follow-up function while the

NC is in the servo OFF state.

The axis detachment function (NC pa-

rameter) is invalid.

(Note) For the axis detachment func-

tion, refer to the NC manual.

Check the investigation item No. 2.

The axis detachment function (NC pa-

rameter) is valid.

(Note) For the axis detachment func-

tion, refer to the NC manual.

Check the investigation item No. 3.

2

Check whether the axis has moved

during servo OFF (either by visual in-

spection or monitor the position droop

waveform).

[1] Check if the motor brake is re-

leased in the middle.

[2] Check if the axis moves because

the servo OFF is applied during the C

axis mode.

[1] The axis has moved.

[2] The servo OFF is applied during

the mode.

[1] Adjust the brakes, etc. so that the

axis does not move.

[2] Avoid the servo OFF from being ap-

plied during position control.

The axis has not moved. Check the investigation item No. 3.

3

Check the excessive error detection

width.

SV026 (Servo)

(Note) Set the same value to SV023.

The excessive error detection width is

too small.

SV026 ={RAPID/(60*PGN1)}/2

Set an appropriate value.

An appropriate value is set.

Check for problems on the NC side,

such as the position FB follow-up con-

trol.

Alarm No.

54

Excessive error 3

When an excessive error 1 occurred, detection of the motor current failed.

Investigation details Investigation results Remedies SV SP

1

Check that the PN voltage is supplied

to the drive unit.

[1] Is the CHARGE lamp ON?

The voltage is not supplied. Correctly supply the PN voltage.

It is correctly supplied (DC300V). Investigate item 2.

2

Check the motor power cable (U, V, W

phases).

[1] The power cable is not connected.

[2] Is the cable connected to the motor

for another axis?

The connections are incorrect. Connect correctly.

The connections are correct. Replace the drive unit.

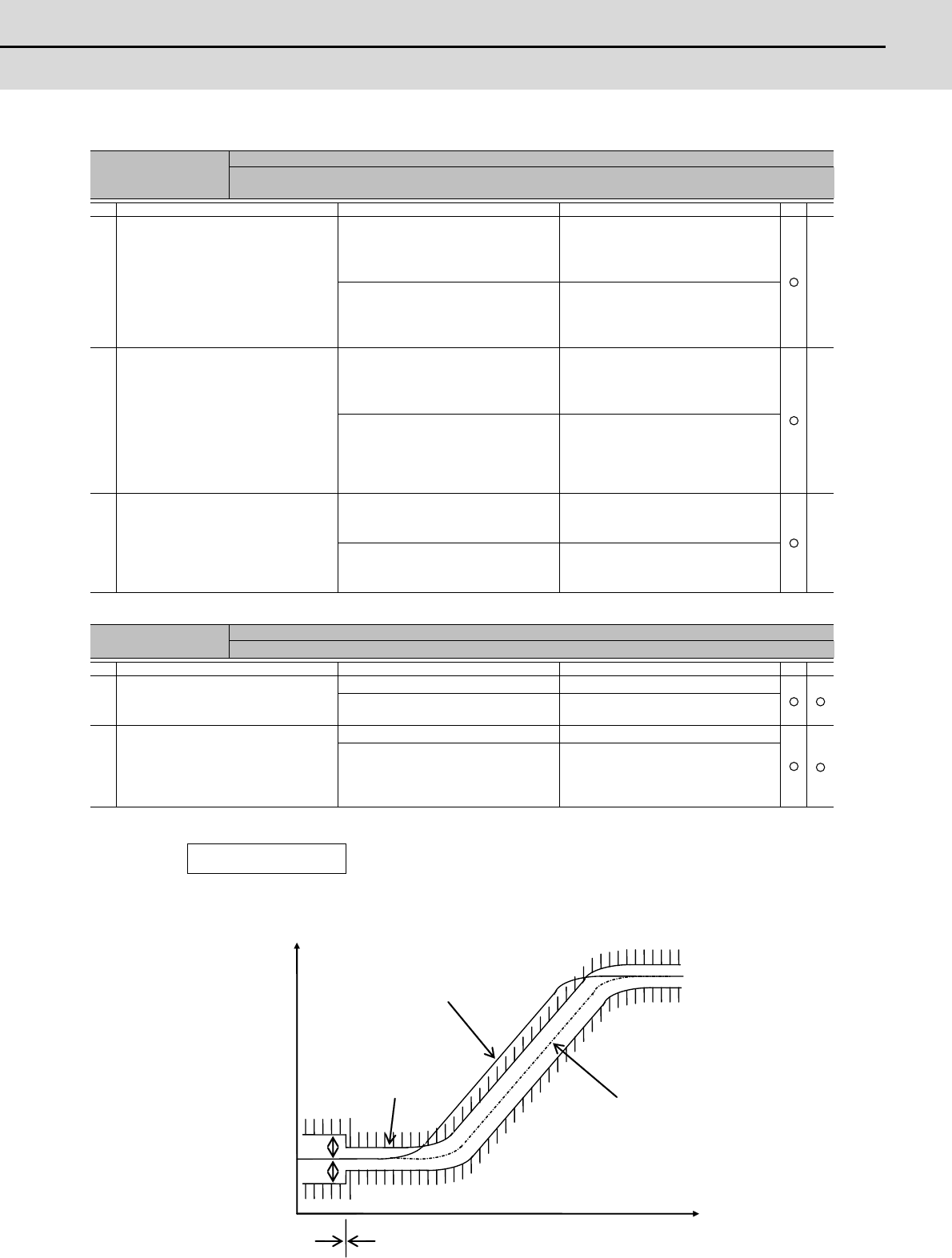

Servo OFF

Servo ON

Time

OD1

OD1

OD2

OD2

Position

Depending on the ideal machine position in respect to the command position, the actual machine

position could enter the actual shaded section shown below, which is separated more than the

distance set in OD1.

Supplement

(servo)

Ideal machine position

Command position