1 - 7

MDS-D-SVJ3/SPJ3 Series Instruction Manual

1-1 Installation of servomotor

1-1-7 Coupling with the load

There are several ways to couple the motor shaft and machine, such as direct coupling with flexible coupling

or rigid coupling, gear connection, timing belt connection, etc.

Summarized comparison is as follows.

(1) Direct coupling - Flexible coupling

When coupling the load directly, a flexible coupling is recommended. The benefits of a flexible coupling

are as below.

(a) Shaft's angle deviation and core deviation can be absorbed to some extent, so adjustment in motor

installation is easier.

However, in the case of single, shaft core deviation cannot be allowed, so it is required to design

and adjust so that the shaft cores of the motor and ball screw align. Check the specification of the

coupling to use. If the shaft core deviation exceeds the coupling's tolerable level, the motor will

have a broken shaft, or the bearing will have a shorter life. Thus, in order to simplify the installation

adjustment, use a double flexible coupling.

(b) Less looseness produces less vibration and less noise at the coupling part.

On the other hand, if assembling is loose, lower rigidity may be caused. When using a coupling with

lower rigidity, the accuracy in centering the core doesn't have to be high, however, it is undesirable

for servo. In order to fully utilize the servo's efficiency to ensure the maximum durability of the

equipments, it is required to use a highly rigid coupling, and to fully align the shaft cores in the initial

installation. It is also required to select the optimum flexible coupling according to the working

conditions, and use it correctly according to the manufacturer's specification manual.

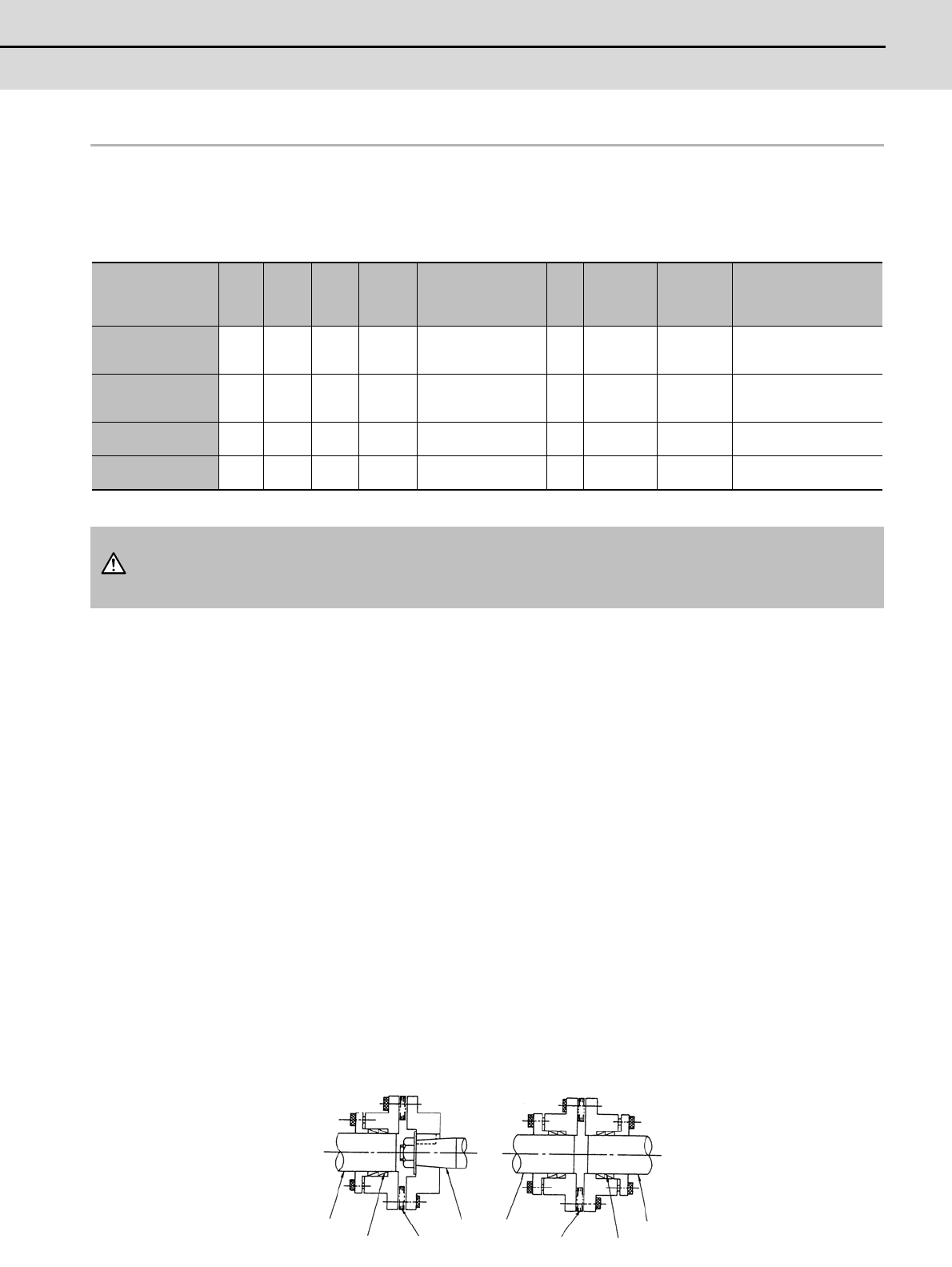

Example of direct coupling with load

Noise

No

lubri-

cation

Back-

lash

Rigidity

Reliability

in coupling

Life

Torque

increased

at deceler-

ation

Degree of

freedom in

motor in-

stallation

Cautions in motor

installation

Direct coupling

with

flexible coupling

Looseness of bolt

Shaft core deviation

(In the case of single)

Direct coupling

with

rigid coupling

Looseness of bolt

Shaft core deviation

Angle deviation

Gear

Tooth chipping

Backlash too small

Pitch diameter too small

Timing belt

Belt is broken

Belt stretched too much

Pitch diameter too small

If the cautions in motor installation in the above table are not observed, the motor will have a broken

shaft, or the bearing will have a shorter life. Carry out design and installation adjustment so that the

load on the motor shaft will be below the tolerable loads mentioned in "1-1-5 Shaft characteristics".

٤

٤

٤

٤

٤

٤

ٌ

٤

٤

٤

٤

٤

٤

ٌ

ٌ

ٌ

ٌ

٤

٤

ٌ

٤

٤ ٤

٤

CAUTION

Load shaft

Spun ring

Flexible coupling

Motor shaft

Load shaft

Spun ring

Flexible coupling

Motor shaft

(a) Taper shaft

(b) Straight shaft