Appendix 5 - 4

Appendix 5 EMC Installation Guidelines

MITSUBISHI CNC

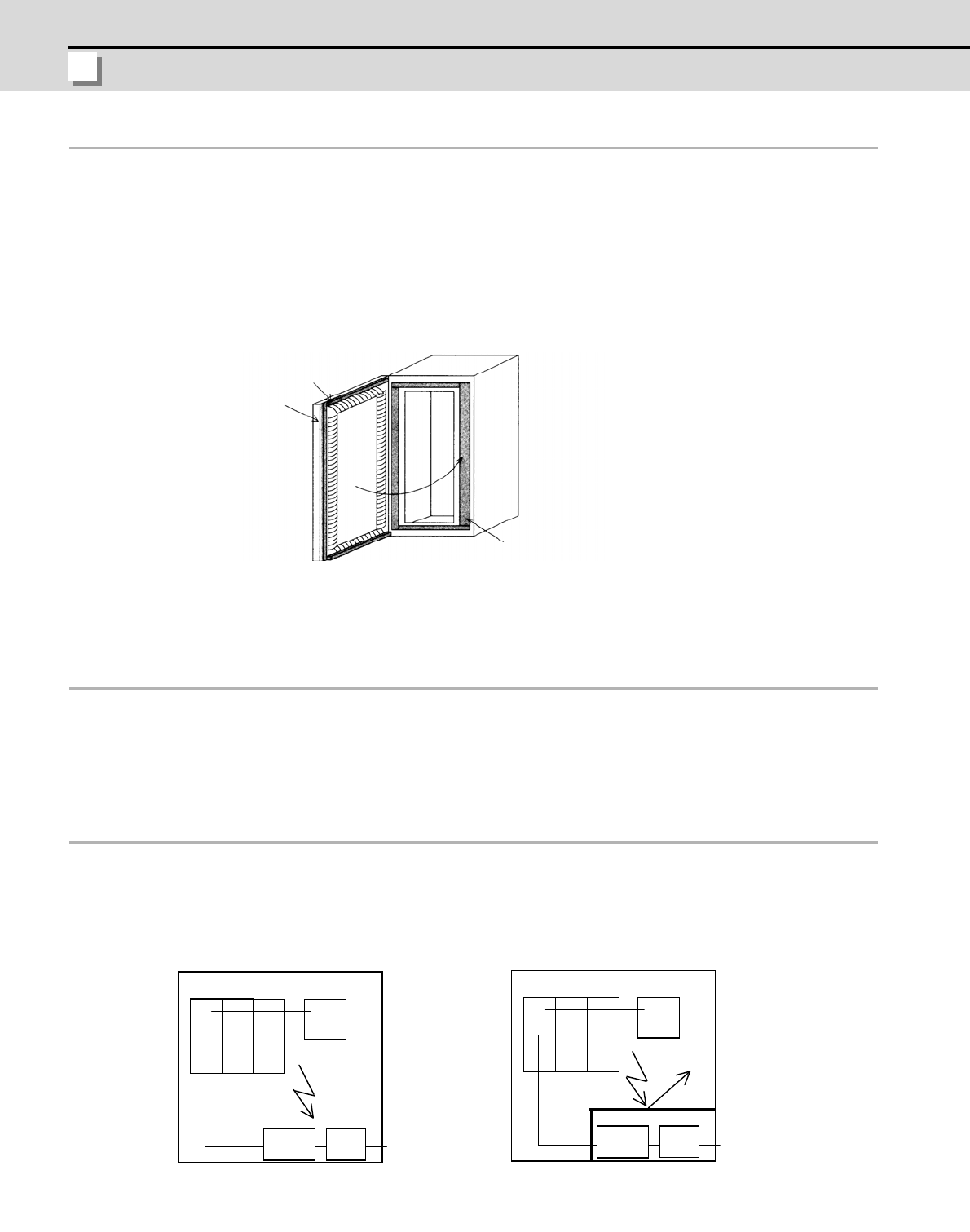

Appendix 5-4-2 Measures for door

[1] Use metal for all materials configuring the door.

[2] Use an EMI gasket or conductive packing for the contact between the door and control panel unit.

[3] The EMI gasket or conductive packing must contact at a uniform and correct position of the metal

surface of the control panel unit.

[4] The surface of the control panel unit contacted with the EMI gasket or conductive packing must have

conductance treatment.

(Example) Weld (or screw) a plate that is plated (with nickel, tin).

[5] As a method other than the above, the control panel unit and door can be connected with a plain

braided wire. In this case, the panel and door should be contacted at as many points as possible.

Appendix 5-4-3 Measures for operation board panel

[1] Always connect the operation board and indicator with an earthing wire.

[2] If the operation board panel has a door, use an EMI gasket or conductive packing between the door and

panel to provide electrical conductance in the same manner as the control panel.

[3] Connect the operation board panel and control panel with a sufficiently thick and short earthing wire.

Appendix 5-4-4 Shielding of the power supply input section

[1] Separate the input power supply section from other parts in the control panel so that the input power

supply cable will not be contaminated by radiated noise.

[2] Do not lead the power line through the panel without passing it through a filter.

EMI gasket

Packing

Control panel

Door

Carry out conductance treatment on

sections that the EMI gasket contacts.

Control panel

Control panel

Drive unit

Drive unit

Radiated

noise

Radiated

noise

AC input AC input

Breaker

Breaker

Power

line filter

Power

line filter

Shielding

plate

The power supply line noise is eliminated

by the filter, but cable contains noise

again because of the noise radiated in the

control panel.

Use a metal plate, etc., for the shielding

partition. Make sure not to create a

clearance.