5 - 28

5 Spindle Adjustment

MITSUBISHI CNC

(3) Setting the notch filter

During spindle C axis operation, there are times where motor is rotated while brake is applied, resulting

in resonance occurred. In this case, measure resonance frequency from q axis current command

waveform and set the value to SP038 (notch filter 1). Also, depending on the set frequency, filter depth

must be set to SP034. When notch filter is set, perform acceleration/deceleration operation at the

maximum speed and confirm that no abnormal oscillation or noise is found.

Notch filter's set frequency and standard depth setting

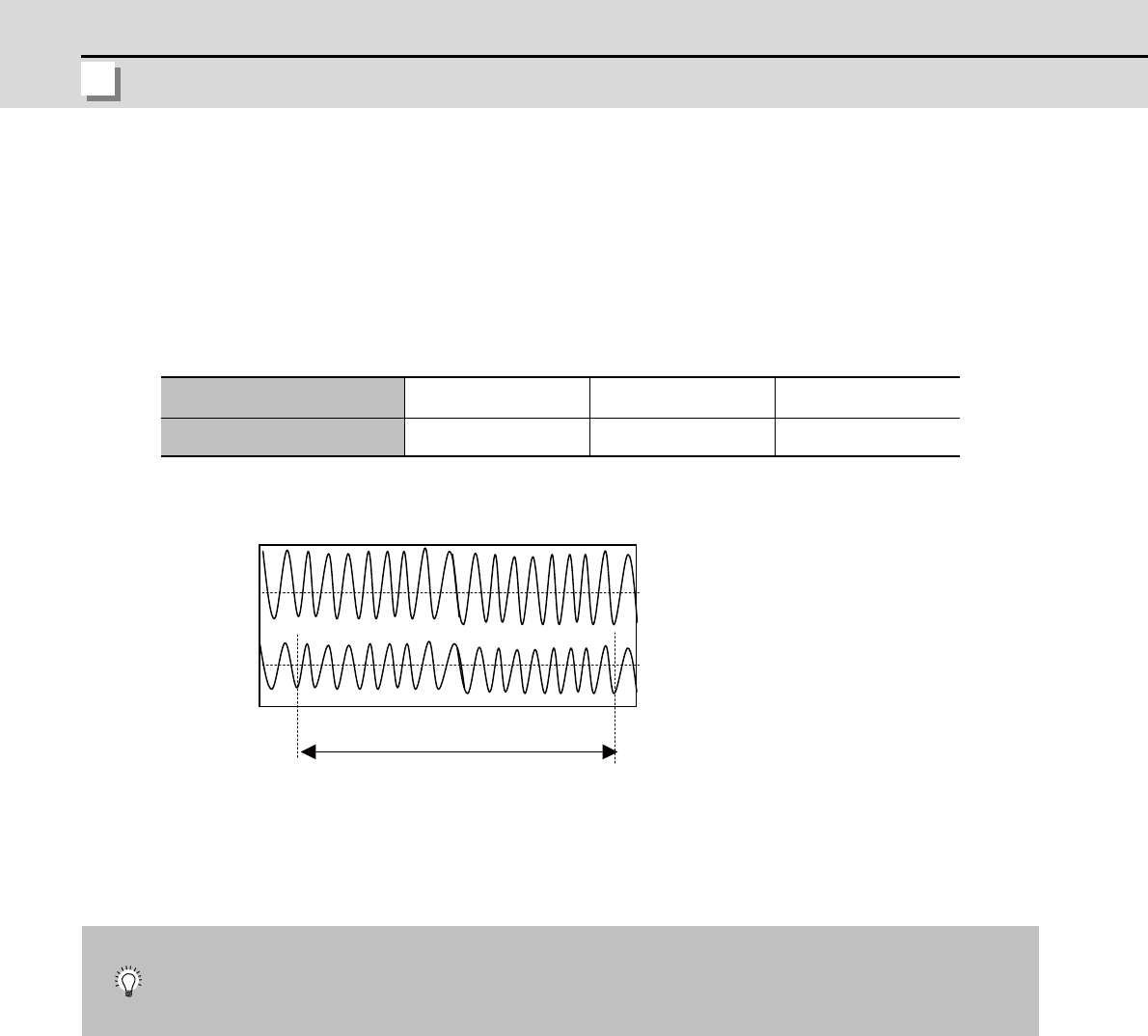

Setting example: When there are 16 wavelengths within 0.02 sec.

Set 800 to SP038 and XXX0 to SP034. Measure position droop and current command at this time, and

adjust notch filter's frequency and depth so that the position droop is within standard range.

SP034

Notch filter 1 Depth setting

bit3=0 bit2=0 bit1=0

Setting value: XXX0

bit3=0 bit2=1 bit1=0

Setting value: XXX4

bit3=1 bit2=0 bit1=0

Setting value: XXX8

SP038

Notch filter 1 Setting frequency

2000(Hz) to 400(Hz) 399(Hz) to 200(Hz) 190(Hz) or lower

1. When incorrect frequency is set, suddenly resonance can occur and big abnormal noise can be

generated. Input the appropriate value.

2. Do not set the value to low-frequency (50Hz).

Ch1: Position

droop

Ch2: q axis current command

0

0

16 wavelengths within 0.02sec = 800Hz

POINT