65

CHAPTER 4 SETTINGS AND PROCEDURE BEFORE OPERATION

4

4.6 Wiring

4.6.1 Wiring precautions

• As a measure against noise, use shielded cables if the cables connected to the module are close (less than

100mm) to a power cable.

Ground the shields of shielded cables to the control panel securely on the module side.

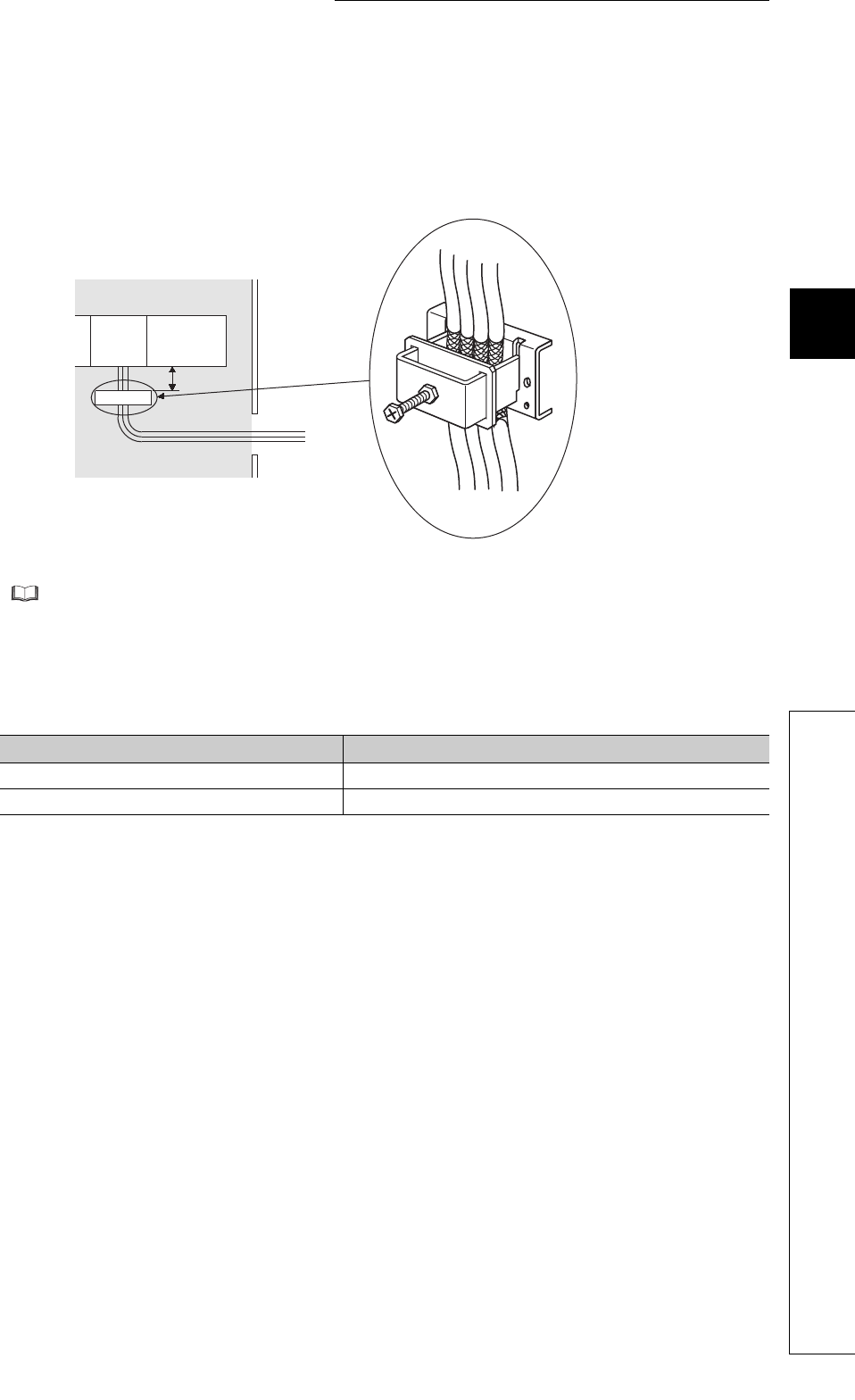

• To comply with EMC and Low Voltage Directives, ground shielded cables to the control panel using the

AD75CK cable clamp (manufactured by Mitsubishi Electric).

(Ground the shield parts at a point within 20 to 30cm from the module.)

For details on the AD75CK, refer to the following.

AD75CK-type Cable Clamping Instruction Manual

• The length of the cable between the module and the drive unit is 1 to 3m generally. The length depends on

the specifications of the drive unit. Review the specifications of the drive unit to be used.

• The length of the cable between the module and the encoder is as listed below generally. The length

depends on the specifications of the encoder. Review the specifications of the encoder to be used. Use

shielded twisted pair cable for the connection with the encoder.

• Connect the module and Servo ON signal of the drive unit without fail. In addition, do not turn on/off Servo

ON signal externally. If Servo ON signal is not connected, the motor may rotate even in case of a CPU error.

Encoder output type Cable length

Differential output type MAX. 30m

TTL type, open collector type MAX. 3m

20 to 30cm

Inside the control panel

AD75CK

QD73A1