4 - 2

MELSEC-

A

4 INSTALLATION, WIRING AND MAINTENANCE OF THE PRODUCT

4.1 Outline of installation, wiring and maintenance

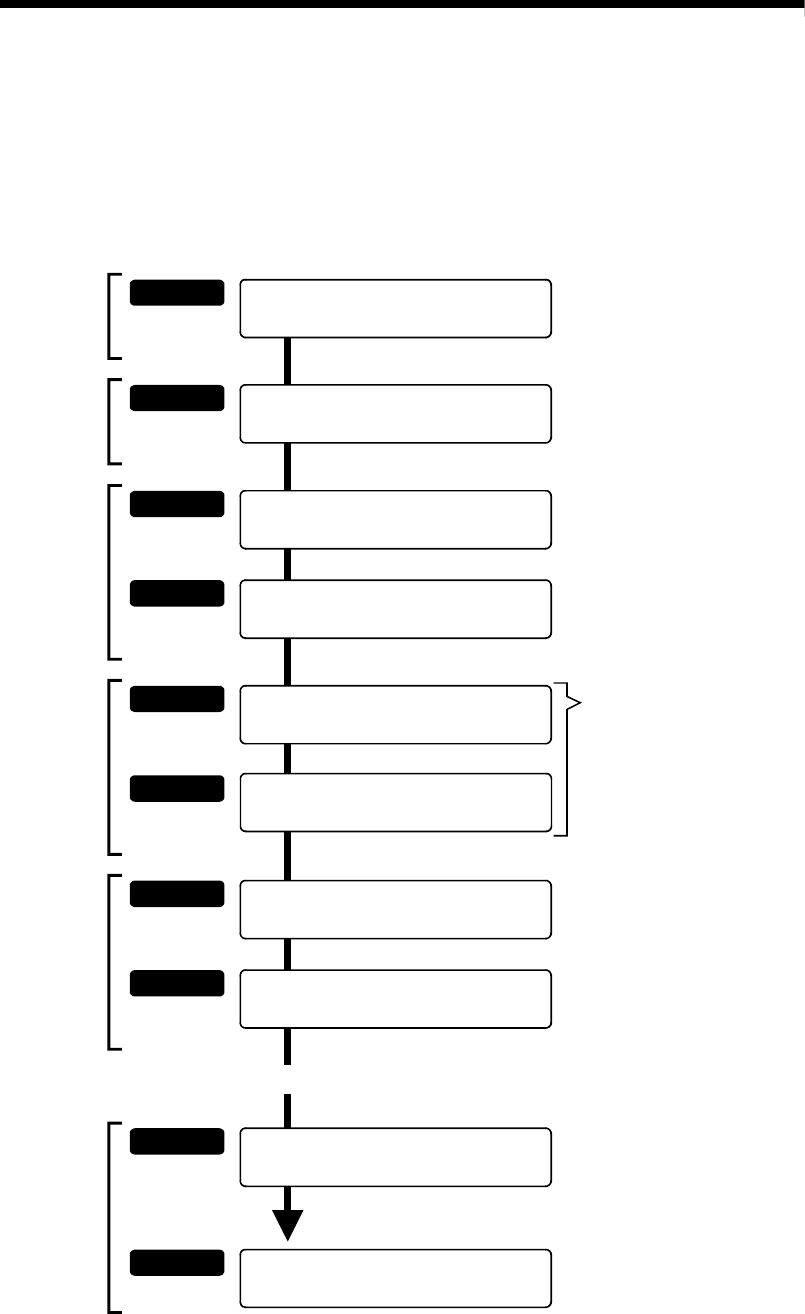

4.1.1 Installation, wiring and maintenance procedures

The outline and procedures for D75P2 installation, wiring and maintenance are shown

below.

STEP 7

STEP 8

STEP 9

STEP 10

Refer to

section 4.8

Refer to

section 4.8

Refer to

section 4.7

Confirmin

g

the

installation and

w

irin

g

Carry out the single module test

Confirm that the D75P2 functions properly

with the single module test.

Servicing the

module

Confirm the connection

Check the connection using the GX Configurator-AP.

Operation of the positioning system.

Carry out maintenance

Carry out maintenance as necessary.

Dispose of the D75P2

When the D75P2 is no longer necessary,

dispose of it with the specified methods.

STEP 5

STEP 6

Refer to

section 4.5

Refer to

section 4.5

Wiring the

drive unit

Wire the external device connection

connector pins, and assemble the connector.

The cables used to connect the D75P2 with the drive

unit, the D75P2 with the machine system input (each

input/output signal), and the D75P2 with the manual

pulse generator are manufactured by soldering each

signal wire onto the "external device connection

connector" enclosed with the D75P2.

Connect the cable to the module (D75P2)

Wire and connect the manufactured cable to D75P2

after reading the precautions for wiring.

*

*

*

*

*

STEP 1

STEP 2

Refer to

section 4.2

Refer to

section 4.1

Preparation

Understand the "Handling precautions" and

"Names of each part" of the module (D75P2)

Installing the

module

Install the module (D75P2) on the

DIN rail/enclosure surface

STEP 3

STEP 4

Refer to

section 4.3

Connection and

settin

g

as

CC-Link

Wire the CC-Link dedicated cables to the

module (D75P2).

Refer to

section 4.4

Set the station number and transmission

speed of the module (D75P2).