Appendix - 40

MELSEC-

A

APPENDICES

POSITION CONTROL

This is mainly the control of position and

dimension, such as in fixed-dimension feed,

positioning, numerical control, etc. This is

always controlled with feed pulses. There is

also speed control.

Drive units may differ, even when the same

motor is used.

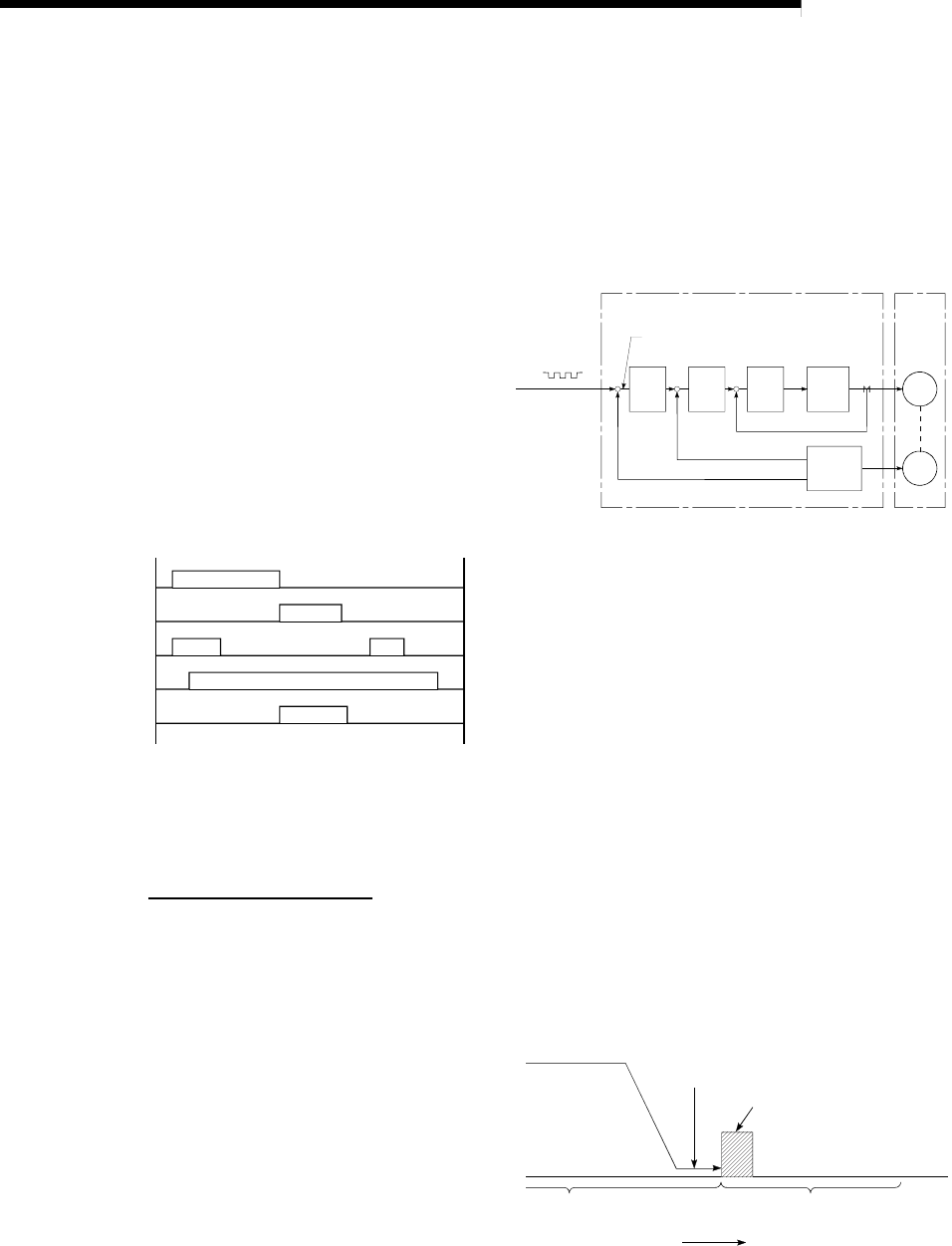

POSITION DETECTION MODULE

This is an abridged version of positioning.

There are two types on MELSEC, the A61LS

and A62LS. This module has positioning and

limit switch functions, and can use a total of 16

channels. The following drawing shows an

example for 5 channels. A resolver is used in

the positioning detection.

ON

ON

ON ON

ON

ON

0 4095

Limit switch LS1

Positioning High speed

Positioning Low speed

Limit switch LS3

Limit switch LS2

POSITION LOOP GAIN

This is the ratio of the deviation counter droop

pulse count to the command pulse frequency.

Position

loop gain

=

Command pulse frequency

(1/s)

Droop pulse count

The position loop gain can be set with the

drive unit. Raise the gain to improve the

stopping accuracy. However, overshooting will

occur if the position loop gain is raised too far,

and the operation will become unstable.

If the position loop gain is lowered too far, the

machine will stop more smoothly but the

stopping error will increase.

POSITION LOOP MODE

This is one servo control mode used in

positioning. It is a mode for carrying out

position control. The other servo control

modes are the speed loop mode for carrying

out speed control, and the torque loop mode

for carrying out torque control (current control).

M

PLG

Servo amplifier Servomoto

r

Pulse train

Droop pulses

Posi-

tion

control

Speed

control

Cur-

rent

control

Inverter

Current feedback

Speed feedback

Position feedback

Interface

POSITIONING

Accurately moving the machine from a point to

a determined point. The distance, direction,

speed, etc., for that movement are designated

by the user. Positioning is used in operations

such as cutting sheets, drilling holes in plates,

mounting parts on a PCB, and welding.

Positioning is also used with robots.

POSITIONING COMPLETE SIGNAL

This is a signal that occurs when the

positioning is complete. A timer set beforehand

starts when this signal is output, and the

machine movement stops for that time.

The purpose of this signal is to start a different

type of work.

The machine will not move to the next

positioning while this signal is ON.

Dwell time

Positioning complete

signal

Positioning Different type of work

Time