Appendix - 31

MELSEC-

A

APPENDICES

CP CONTROL (Continuous Path Control)

Continuous path is a control method in which a

path is followed without interrupting such as in

uniform speed control.

CREEP SPEED

A speed at which the machine moves very

slowly.

It is difficult for the machine to stop accurately

when running at high speed, so the movement

must first be changed to the creep speed before

stopping.

Refer to the term "NEAR-POINT DOG".

CURRENT FEED VALUE

The zero point address at the completion of the

machine zero point return is stored.

The position currently being executed is stored.

This value changes when the current value is

changed.

CURRENT LOOP MODE

This is one servo control mode used in

positioning. It is a mode for controlling the

torque using the current. Also called the torque

loop mode. Refer to "POSITIONING LOOP

MODE".

CURRENT VALUE

This is the current address (position) when

stopped or during positioning.

CURRENT VALUE CHANGE

The D75P2 has no way of knowing the current

value when the machine is assembled and the

D75P2 is connected, so this function is used to

teach it a temporary approximate value as the

current value. This function can also be used

to write a temporary current value when the

current value has been lost due to accidents,

etc. If a machine zero point return is carried

out after that, the D75P2 will recognize the

zero point.

In fixed-dimension feed, etc., rewriting the

current value to 0 after the fixed-dimension

feed will keep the accumulated value from

being affected by the stroke limit. The current

value can be changed during a positioning

stop.

CW (Clockwise)

Rotation in the clockwise direction. Rotation in

the clockwise direction looking from the motor

shaft end side.

D/A CONVERTER (Digital-to-Analog

converter)

A device having a function to convert the

digital value expressing the No. of pulses to an

analog value expressing the voltage (or

current).

No. of pulses

0 to 80,000

pulses/second

D/A Voltage 0 to ±10V.

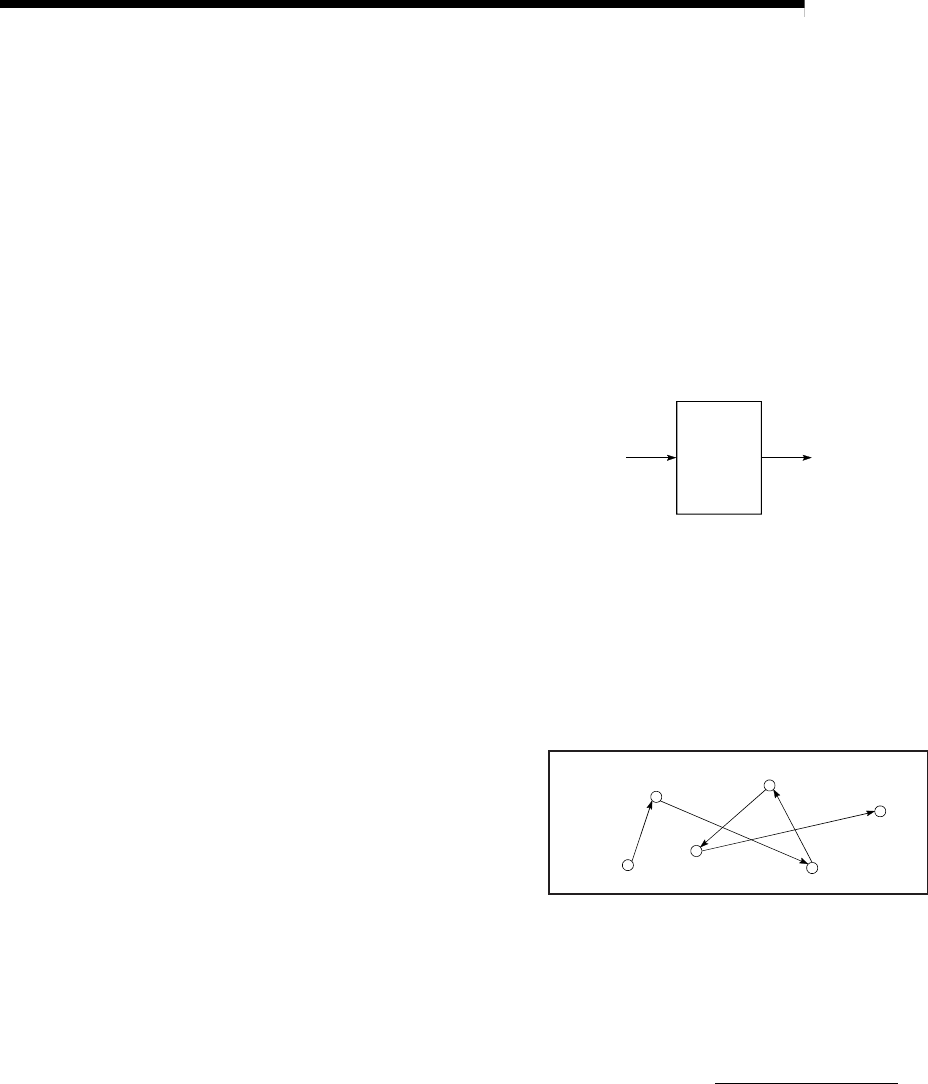

DATA NO.

To carry out positioning to 2 or more

addresses, each position is assigned a

sequence No. such as No. 1, No. 2, No. 3, etc.

The positioning is then carried out following

this sequence. The D75P2 is capable of

positioning up to No. 600.

No.1

No.2

No.3

No.4

No.5

No.

6

DECELERATION RATIO

A ratio used when the machine is decelerated

using a toothed gear. This ratio is a numeral

larger than 1.

Deceleration

ratio

=

Input gear speed

Output gear speed