8 - 15

MELSEC-

A

8 ZERO POINT RETURN CONTROL

Restrictions

(1) Always limit the servomotor torque after the "

Pr.49 Creep speed" is reached.

If the torque is not limited, the servomotor may fail when the machine presses

against the stopper. (Refer to section "12.4.2 Torque limit function".)

(2) Use an external input signal as the zero point signal.

(3) The zero point retry function cannot be used in "stopper stop method 3)".

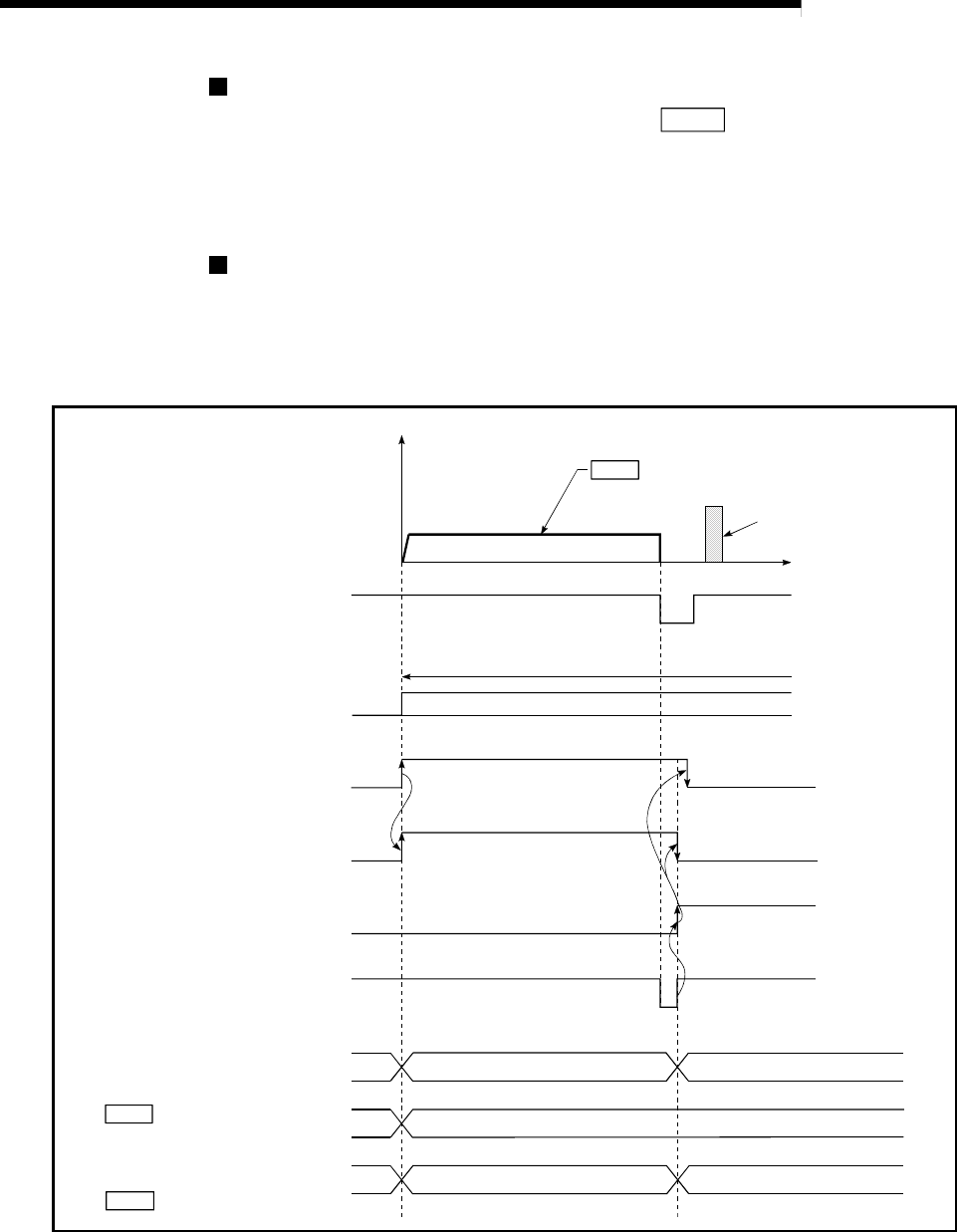

Precautions during operation

(1) If the zero point signal is input before the workpiece stops at the stopper, the

workpiece will stop at that position, and that position will become the zero

point.

At this time, an error will not occur.

t

ON

OFF

ON

OFF

OFF

ON

V

0

Pr. 49 Creep speed

Valid torque limit range

Machine zero point return start

(Positioning start signal)

Axis operation status

[RWrn+7, RWrn+15]

Value the machine moved is stored

Zero point return request flag

[RX(n+1)F, RX(n+4)F]

Zero point return complete flag

[RX(n+2)0, RX(n+5)0]

Md.44 Movement amount

after near-point dog ON

Current feed value

[RWrn+0 to 1, RWrn+8 to 9]

Zero point address

Inconsistent

Standing by

In zero point return

Inconsistent

Standing by

Md.30 Machine feed value

Torque limit

Zero point signal

Deviation counter clear output

Stopper

Fig. 8.10 When the zero point signal is input before the stop at the stopper

(2) If the restart command is turned ON after machine zero point return is stopped

upon a stop signal, an error “zero point return restart not possible” (error code:

209) occurs.