Appendix - 47

MELSEC-

A

APPENDICES

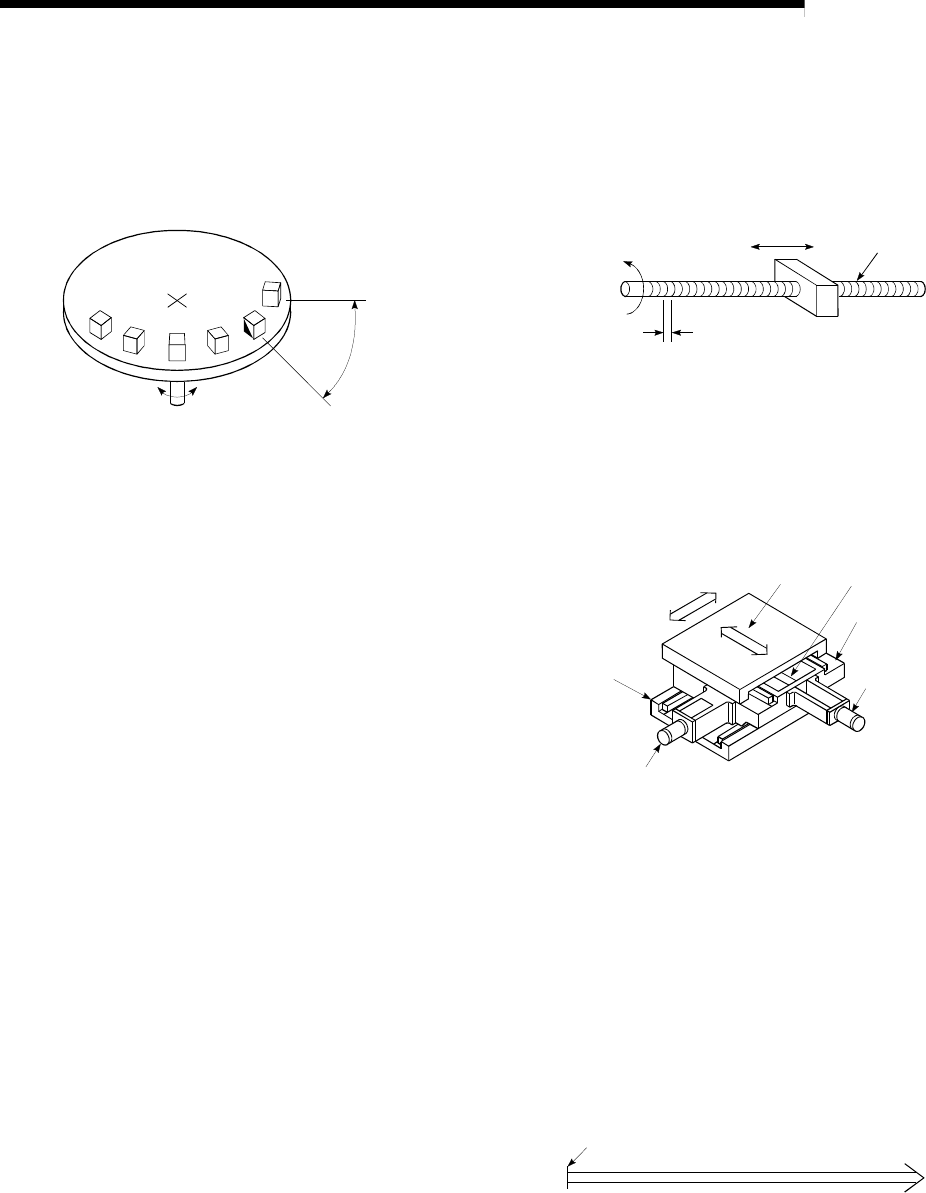

TURNTABLE

A rotating table, which is turned using power.

The table is used divided from one 360

°

rotation into the required locations for work.

The positioning control unit is "degree".

Rotated by the motor

30°

UNIT SETTING

This is the setting of the unit for the actual

address to which positioning is required, or for

the movement amount.

The following units can be set: mm, inch,

degree and pulse. The initial value in the

parameters is a pulse unit.

WARNING

A warning is output as a warning code in when

an abnormality is detected that is not serious

enough to require cancellation or stoppage of

the positioning operation. Warnings are

handled differently than errors.

WITH MODE

This is the mode that outputs the M code

before the start of the positioning. This mode

turns ON at the positioning start, enabling

voltage to be applied to the welding

electrodes, display of positioning speeds, etc.

Refer to the term "AFTER MODE".

WORM GEAR

This is the basic screw in mechanisms that

position using screw rotation. Ball screws are

often used to reduce backlash and dimension

error.

1 rotation

by the motor

Positioning

Worm gear

Lead (feedrate per screw rotation)

XY TABLE

This is a device that moves a table in the X

(latitudinal) and Y (longitudinal) directions so

that positioning can be carried out easily.

There are also commercially available

products.

X table

Y table

Ball scre

w

X table

Base table

Y axis

X axis

Z PHASE

Also called "PG zero". Refer to "ZERO POINT

SIGNAL".

ZERO POINT

This is the reference position for positioning.

Positioning cannot start without a reference

point.

The zero point is normally set to the upper or

lower stroke limit.

Z

ero point

This point is the reference.