1 - 4

MELSEC-

A

1 PRODUCT OUTLINE

1.1.2 Purpose and applications of positioning control

"Positioning" refers to moving a moving body, such as a workpiece or tool (hereinafter,

generically called "workpiece") at a designated speed, and accurately stopping it at the

target position. The main application examples are shown below.

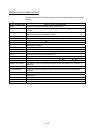

Punch press (X, Y feed positioning)

Y axis

servomotor

Gear and ball screw

Y axis

X axis

Y axis

320mm

160mm

15m/min

(2000r/min)

15m/min

(1875r/min)

12 s

Press head

Servo

a

mplifier

X axis

Gear and rack & pinion

X axis

servomotor

X axis

Y axis

Servo

amplifier

Press

punching

D75P2

To punch insulation material or leather, etc.,

as the same shape at a high yield, positioning

is carried out with the X axis and Y axis

servos.

After positioning the table with the X axis

servo, the press head is positioned with the Y

axis servo, and is then punched with the

press.

When the material type or shape changes, the

press head die is changed, and the positioning

pattern is changed.

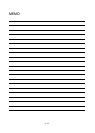

Palletizer

Servo amplifier

Conveyor control

Conveyor

Servomotor

(with brakes)

Position detector

Reduction

gears

Ball screw

(From D75P2)

Palletizer

Unloader control

G

D75P2

Using the servo for one axis, the palletizer is

positioned at a high accuracy.

The amount to lower the palletizer according to

the material thickness is saved.

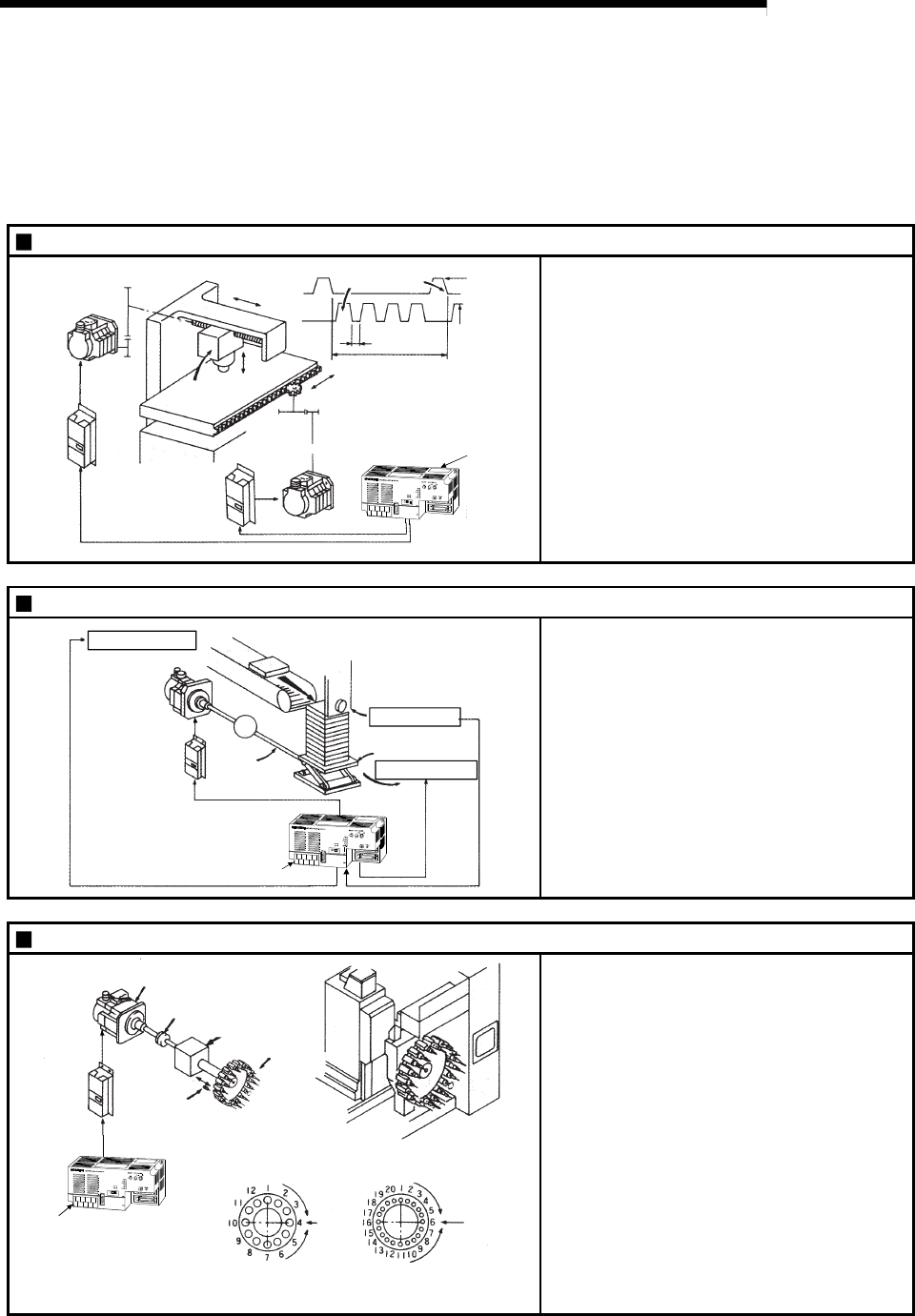

Compact machining center (ATC magazine positioning)

Servomotor

Servo

amplifier

Coupling

ATC tool

magazine

Reduction

gears

Positioning

pin

Tool

(12 pcs., 20 pcs.)

<No. of tools: 12> <No. of tools: 20>

Current

value

retrieval

position

Current

value

retrieval

position

Rotation direction

for calling

11, 12, 1, 2 or 3

Rotation direction

for calling

17 to 20, 1 to 5

Rotation direction

for calling 5, 6, 7, 8, 9 or 10

Rotation direction

for calling 7 to 16

D75P2

The ATC tool magazine for a compact

machining center is positioned.

The relation of the magazine's current value

and target value is calculated, and positioning

is carried out with forward run or reverse run to

achieve the shortest access time.