Appendix - 52

MELSEC-

A

APPENDICES

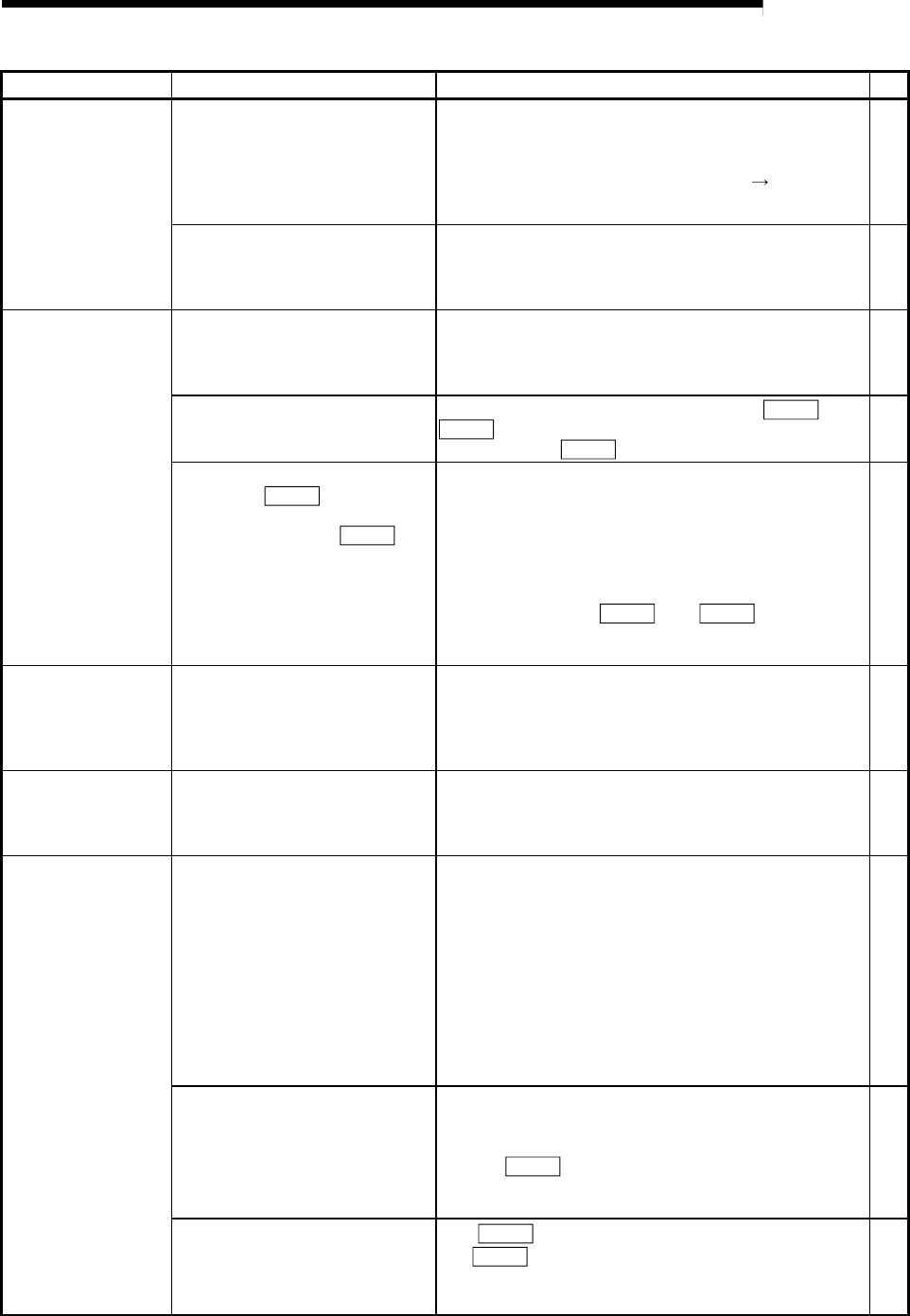

Trouble type Questions/Trouble Remedy No.

Start

The positioning start signal

[RY(n+1)0] is kept ON until the

BUSY signal is OFF, but is there

any problem with turning it OFF

before the BUSY signal turns

OFF?

After the BUSY signal turns ON, there is no problem with

turning [RY(n+1)0] OFF before the BUSY signal turns

OFF.

(The D75P2 detects the rising edge (OFF

ON) of the

positioning start signal [RY(n+1)0].)

27

The operation will not start even

when the start signal is turned ON.

Check the "axis operation status (Rwrn+7, RWrn+15)"

and "axis error No. (Rwrn+5, RWrn+13)"

Review the sequence program and normalize the start

timing.

28

Stop

How many ms should the axis stop

signal [RY(n+1)3] be turned ON

for?

The signal should be turned ON at 4ms or more.

(If possible, set the signal so it does not turn ON only

momentarily, but instead stays ON until the BUSY signal

turns OFF. This will keep the stop signal from skipping.)

29

How can a sudden stop be

selected?

Set "1: Sudden stop" in the parameter from

Pr.38 to

Pr.40 corresponding to the stop group, and reduce the

setting value of "

Pr.37 Sudden stop deceleration time".

30

"Normal deceleration stop" was

selected in "

Pr.40 Stop group 3

sudden stop selection", and Y stop

was turned ON. If the

Pr.40

setting is changed to "sudden

stop" during a deceleration stop,

and the Y stop signal turns from

OFF to ON, will the operation

change to a sudden stop from that

point?

The operation will not change.

Even if the same stop factor is input again during the

deceleration stop, it will be ignored. The same

deceleration stop process used when the stop signal was

first input will be continued.

(This also applies for

Pr.38 and Pr.39 .)

31

Circular interpolation

ABS type circular interpolation

operates normally, but a vertically

oblong circle results when INC

type circular interpolation is carried

out.

The address designation may be incorrect. When carrying

out INC type circular interpolation, designate the relative

addresses from the starting point of both the center point

and end point.

32

Speed/position

changeover control

Can the speed be changed during

speed control and position control

by speed/position changeover

control?

The speed during speed control and position control

cannot be set separately, but a speed change is possible

if executed after the speed/position changeover signal

turns ON.

33

JOG operation

Even if the JOG start signal is

turned ON, the response until it

turns ON is sometimes slow.

Either of the following is possible.

1) The sequence program may be incorrect. Check by

creating a test program in which the JOG start signal

is turned ON only.

2) If the machine is hitting something when the torque

setting is low, it may be trying to move by JOG

operation in the opposite direction. In this case, the

machine will start moving only after the internal droop

pulses have been reached 0 in the counter, even if the

JOG start signal has been turned ON. This makes it

seem that the response is slow.

34

The operation is not carried out at

the set JOG speed, although the

speed limit value has not been

reached.

Either of the following is possible.

1) The JOG start signal may be chattering. Monitor the

JOG start signal to confirm whether it is chattering.

2) The "

Pr.32 JOG speed limit value" may not be

appropriate. Review the setting value and carry out

the JOG operation again.

35

When a JOG operation is

attempted, an error results and the

machine does not move.

The "

Pr.32 JOG speed limit value" may be larger than

the "

Pr.7 Speed limit value".

Review the parameters and carry out the JOG operation

again.

36