1 - 7

MELSEC-

A

1 PRODUCT OUTLINE

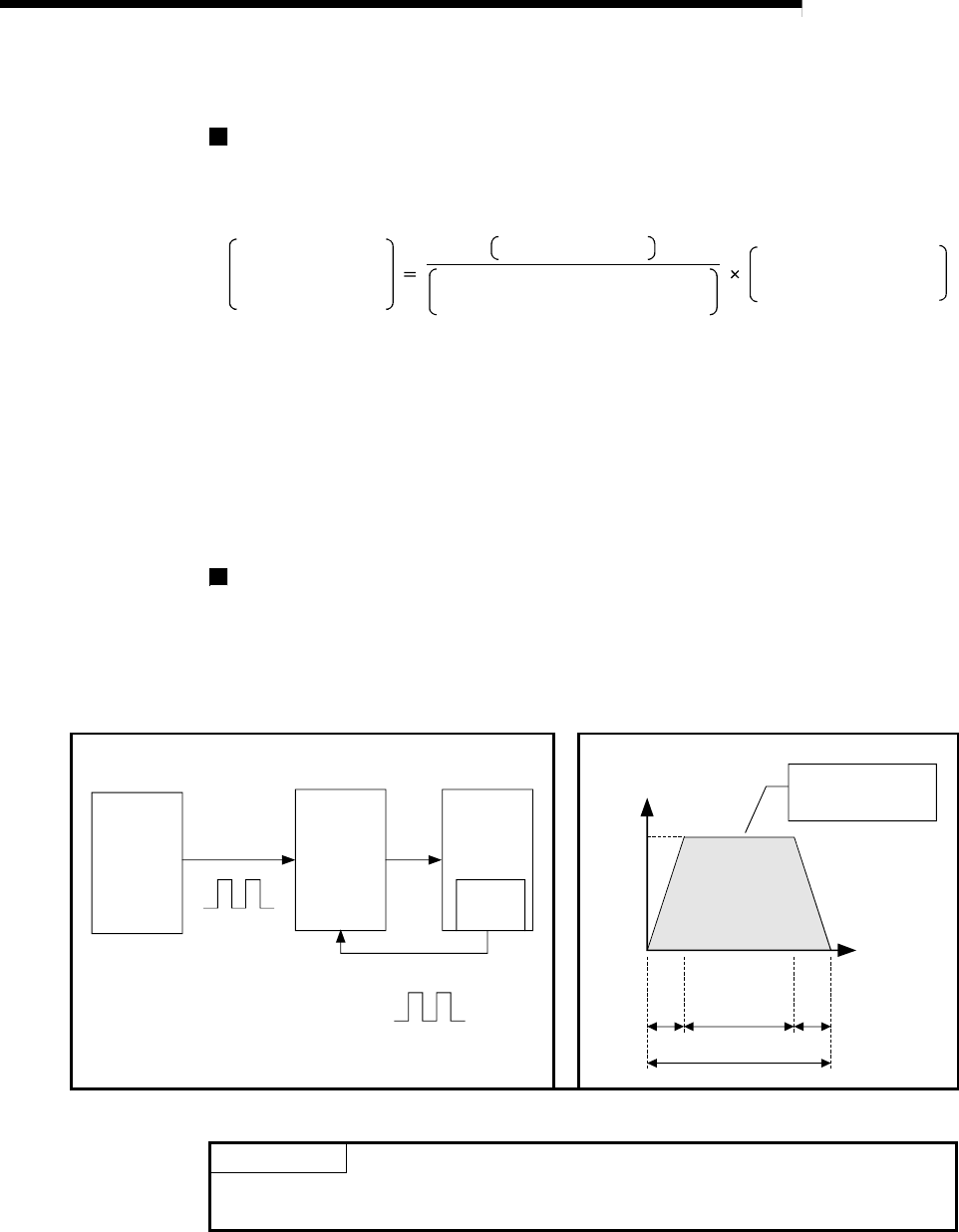

The principle of "position control" and "speed control" operation is shown below.

Position control

The total No. of pulses required to move the designated distance is obtained in the

following manner.

Total No. of pulses

required to move

designated distance

No. of pulses required for

motor to rotate once

Designated distance

Movement amount of machine (load)

side when motor rotates once

* The No. of pulses required for the motor to rotate once is the "encoder resolution"

described in the motor catalog specification list.

When this total No. of pulses is issued from the D75P2 to the servo amplifier, control to

move the designated distance can be executed.

The machine side movement amount when one pulse is issued to the servo amplifier is

called the "movement amount per pulse". This value is the min. value for the workpiece

to move, and is also the electrical positioning precision.

Speed control

The above "total No. of pulses" is an element required for movement distance

control, but when carrying out positioning control or speed control, the speed must

also be controlled.

This "speed" is controlled by the "pulse frequency".

Positioning

module

Servo

amplifier

Servomotor

Detector

Speed = Pulse frequency

Movement amount = No. of pulses

Feedback pulses =

Pulses generated by detector

Feedback pulse

(Pulse

encoder)

A

ta td

0.4 1.2 0.4

(s)

Pulse frequency

[pps]

This area is the total

No. of commanded

pulses.

Movement amount t = 2

Fig. 1.1 Relationship between position control and speed control

POINT

The D75P2 controls the position with the "total No. of pulses", and the speed with

the "pulse frequency".