8 - 11

MELSEC-

A

8 ZERO POINT RETURN CONTROL

8.2.5 Zero point return method (3): Stopper stop method 2)

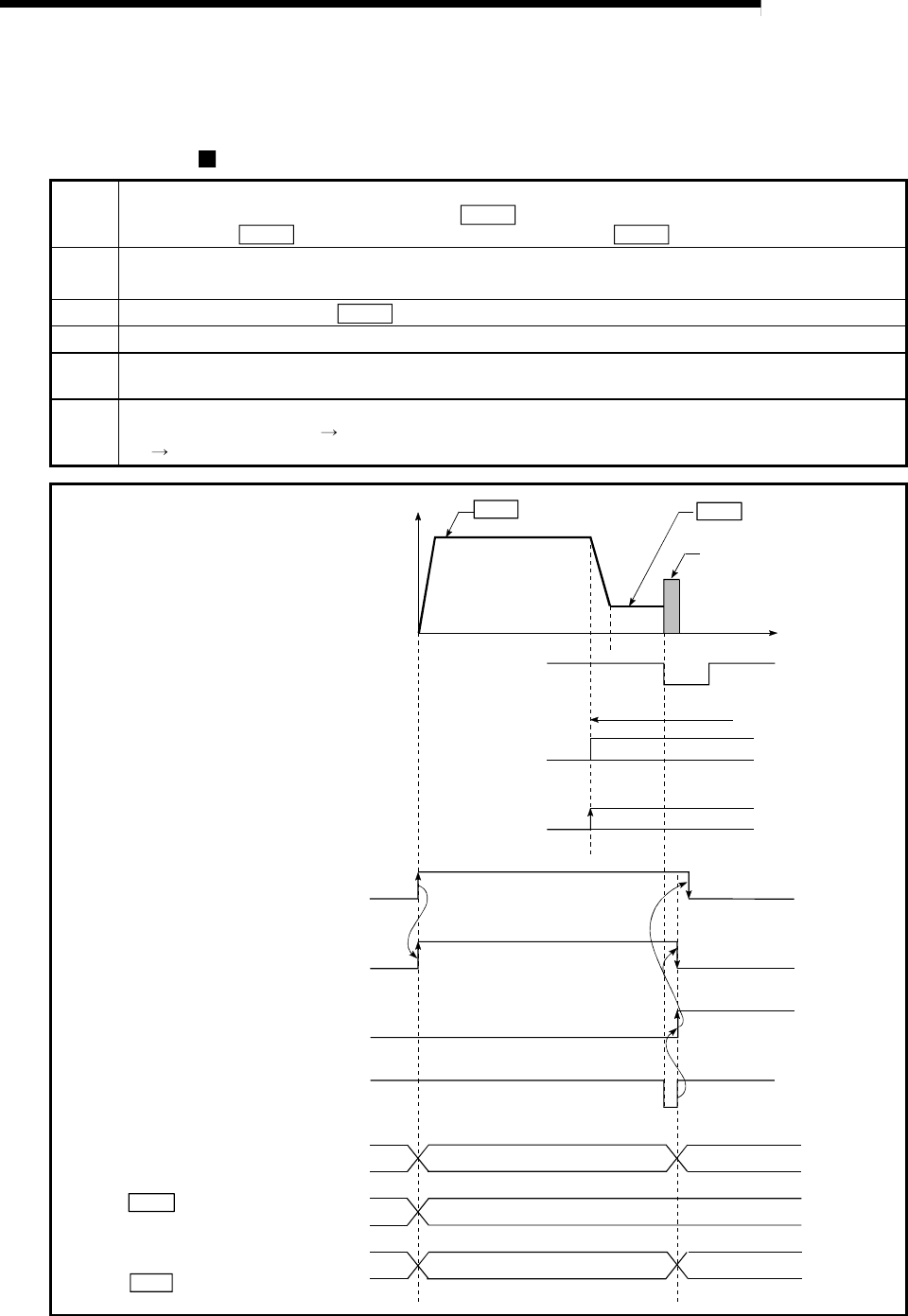

The following shows an operation outline of the "stopper stop method 2)" zero point

return method.

Operation chart

1)

The machine starts a machine zero point return.

(The machine starts acceleration specified in "

Pr.53

Zero point return acceleration time selection" in the

direction set in "

Pr.46

Zero point return direction", and moves at " Pr.48 Zero point return speed".)

2)

The machine detects near-point dog ON and starts deceleration.

(At this time, torque limit is required. If torque limit is not applied, the servomotor may fail at 4).)

3)

The machine decelerates to "

Pr.49 Creep speed" and then moves at the creep speed.

4) The machine comes into contact with the stopper at the creep speed, and stops.

5)

At the zero point signal after the stop, pulse output from the D75P2 stops and "deviation counter clear

output" is output to the drive unit.

6)

After the completion of "deviation counter clear output", the zero point return complete flag (RX(n+2)0,

RX(n+5)0) turns from OFF ON and the zero point return request flag (RX(n+1)F, RX(n+4)F) turns from

ON

OFF.

Machine zero point return start

(Positioning start signal)

Deviation counter clear output

Axis operation status

[RWrn+7, RWrn+15]

Zero point return request flag

[RX(n+1)F, RX(n+4)F]

Zero point return complete flag

[RX(n+2)0, RX(n+5)0]

Md.44 Movement amount

after near-point dog ON

Current feed value

[RWrn+0 to 1, RWrn+8 to 9]

Md.30 Machine feed value

t

ON

OFF

ON

OFF

OFF

ON

0

V

ON

Zero point signal

1)

2) 3) 4)

Pr. 48 Zero point return speed

Pr. 49 Creep speed

Stops at stopper

6)

5)

Valid torque limit range

Near-point dog OFF

Torque limit

Standing by

Inconsistent

Inconsistent

In zero point return

Value the machine moved is stored

Standing by

Zero point address

Fig. 8.6 Stopper stop method 2) machine zero point return