11 - 4

MELSEC-

A

11 MANUAL CONTROL

11.2 JOG operation

11.2.1 Outline of JOG operation

Important

Use the hardware stroke limit function when carrying out JOG operation near the

upper or lower limits. (Refer to section 12.4.4).

* If the hardware stroke limit function is not used, the workpiece may exceed the

operating range, causing an accident.

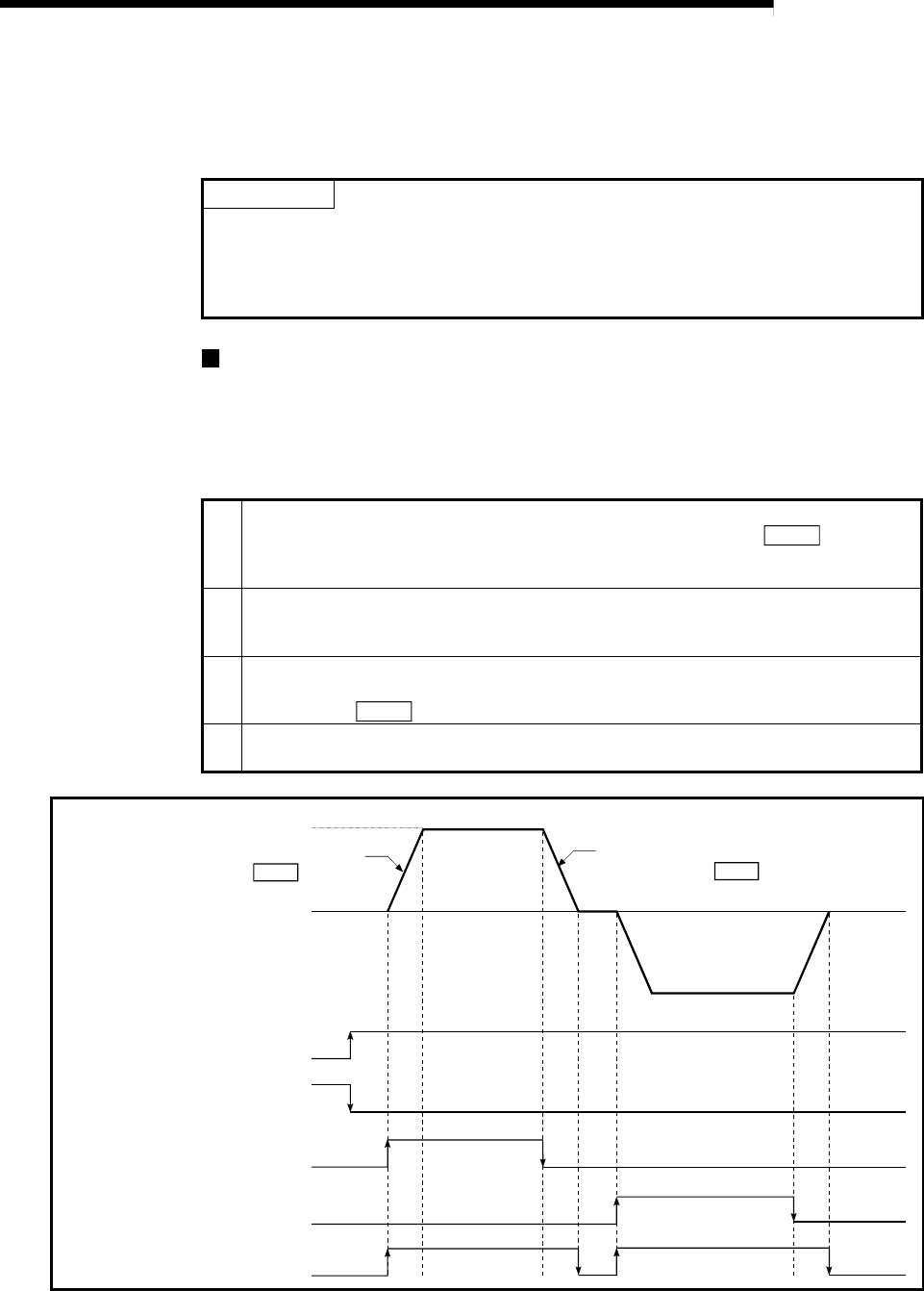

JOG operation

In JOG operation, the Forward run JOG start signal [RY(n+1)6, RY(n+1)8] or

Reverse run JOG start signal [RY(n+1)7, RY(n+1)9] turns ON, causing pulses to

be output to the drive unit from the D75P2 while the signal is ON. The workpiece is

then moved in the designated direction.

The following shows examples of JOG operation.

1)

When the START signal turns ON, acceleration begins in the direction designated by the

START signal, and continues for the acceleration time designated in "

Pr.33 JOG

operation acceleration time selection". At this time, the BUSY signal changes from OFF to

ON.

2)

When the workpiece being accelerated reaches the speed set in "JOG speed (RWwm+6

to 7, RWwm+14 to 15)", the movement continues at this speed.

Constant speed operation takes place at 2) and 3).

3)

When the START signal is turned OFF, deceleration begins from the speed set in "JOG

speed (RWwm+6 to 7, RWwm+14 to 15)", and continues for the deceleration time

designated in "

Pr.34 JOG operation deceleration time selection".

4)

The operation stops when the speed becomes 0. At this time, the BUSY signal changes

from ON to OFF.

Remote station READY signal

OFF

ON

Reverse run JOG start signal

OFF

ON

OFF

ON

BUSY signal

OFF

ON

Forward JOG run

Reverse JOG run

ON

OFF

D75P2 READY signal

Forward run JOG start signal

JOG speed

(RWwm+6 to 7, RWwm+14 to 15)

Acceleration for the acceleration

time selected in Pr. 33

Deceleration for the deceleration

time selected in Pr. 34

1) 2) 3) 4)

[RX(n+7)B]

[RXn0]

[RY(n+1)6, RY(n+1)8]

[RY(n+1)7, RY(n+1)9]

[RXn4, RXn5]

Fig. 11.3 JOG operation