Appendix - 28

MELSEC-

A

APPENDICES

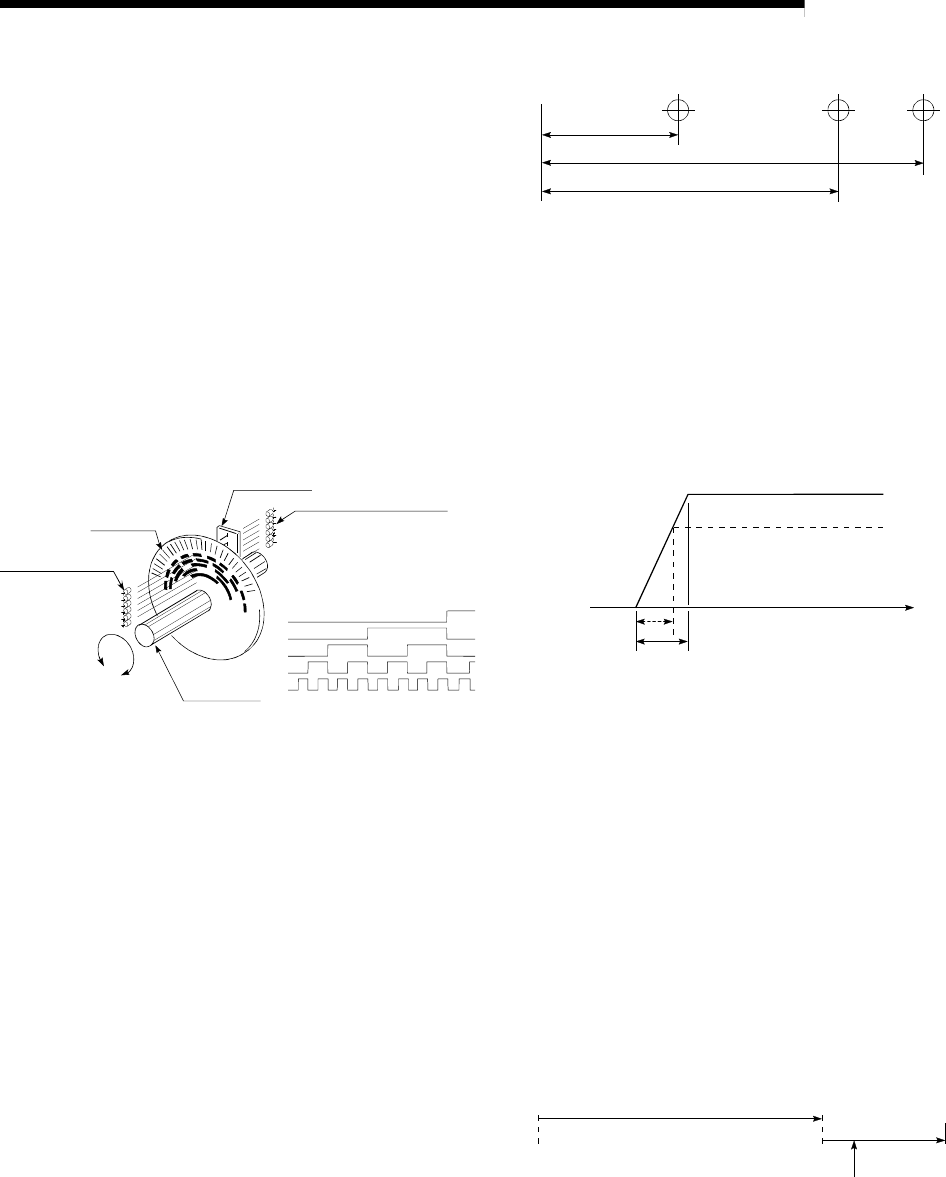

ABSOLUTE ENCODER

This is a detector that enables the angle data

within 1 motor rotation to be output to an

external destination. Absolute encoders are

generally able to output 360

°

in 8 to 12 bits.

Incremental encoders have a disadvantage in

that the axis position is lost when a power

failure occurs. However, with absolute

encoders, the axis position is not lost even

when a power failure occurs.

Various codes such as a binary code and BCD

code can be output.

Absolute encoders are more expensive, more

accurate, and larger than incremental

encoders. Refer to "ENCODER".

2

2

2

2

0

1

3

4

2

4

2

3

2

2

2

1

2

0

Slit disk

Phototransistor

Fixed slit

Light-emitting diode

Rotating

axis

Binary code

ABSOLUTE POSITION DETECTION

SYSTEM

When positioning is carried out using this

system, a zero point return can be carried out

once when the device is started to allow the

machine position to be stored in the memory

and the current position to be held even when

the power is turned OFF. These will be

compensated if mechanical deviation occurs,

so a zero point return is not required after the

power is turned ON again. A motor with an

absolute position detector and servo amplifier

and positioning module compatible with an

absolute position detection system are

required to configure this system.

ABSOLUTE SYSTEM

This is one system for expressing a positioning

address.

Absolute address system.

This system uses 0 as a reference, and

expresses the address as the distance from 0.

The direction is automatically determined,

even when it is not designated. The other

address system is the increment system.

No.10 No.2 No.3

ACCELERATION TIME

The parameter acceleration time refers to the

time from a stopped state to the time the

speed limit value is reached, so it becomes

proportionally shorter as the setting speed

decreases. The acceleration time is

determined by factors such as machine inertia,

motor torque, and load resistance torque.

Speed limit value

Setting speed

Speed 0

Acceleration time

Time

ADDRESS

1) This is a numerical value to express the

positioning position, designated in mm, inch,

angle, or No. of pulse units.

2) The memory address. Many addresses are

stored in the memory. An address is read or

written after it is designated.

AFTER mode

This is the mode that outputs the M code after

positioning is complete (after stopping).

Clamping can be commanded, drilling

dimensions can be selected, etc., with this

mode.

OFFON

No.11No.10

Positioning

M code (8)

Clam

p

command