1 - 17

MELSEC-

A

1 PRODUCT OUTLINE

1.2.4 Outline for restarting

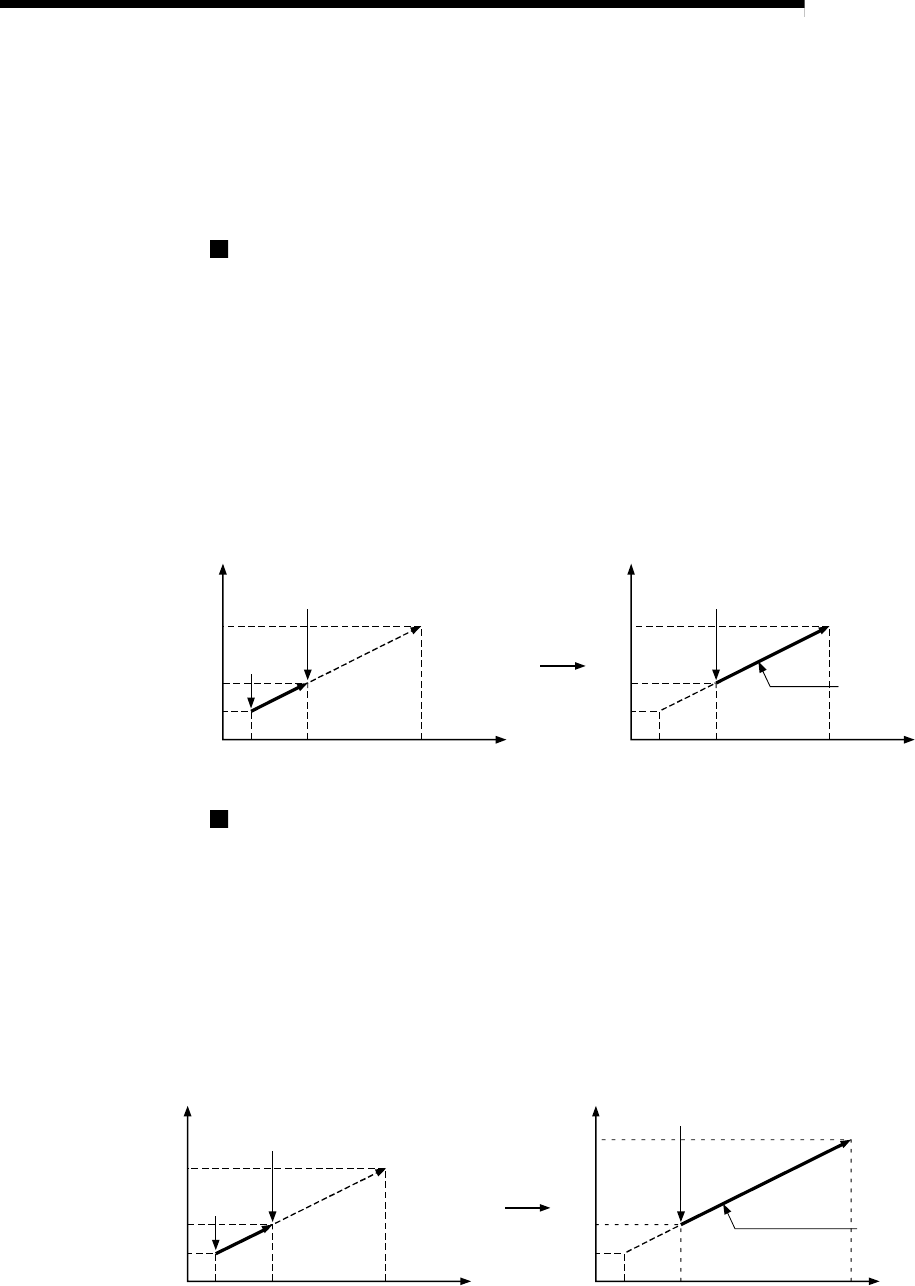

When a stop cause has occurred during operation with position control causing the

axis to stop, positioning to the end point of the positioning data can be restarted from

the stopped position by using restart command [RY(n+2)5, RY(n+4)5].

When "Restart command [RY(n+2)5, RY(n+4)5]" is ON

(1) If the "Axis operation status (RWrn+7, RWrn+15)" is stopped, positioning to

the end point of the positioning data will be restarted from the stopped position

regardless of the absolute method or incremental method.

(2) When "Axis operation status (RWrn+7, RWrn+15)" is not stopped, the warning

"restart not possible" (warning code: 104) will be applied, and the restart

command will be ignored.

[Example for incremental method]

The restart operation when the axis 1 movement amount is 300, and the axis 2

movement amount is 600 is shown below.

4

00

200

100

100 300 700

400

200

300 700

100

100

Axis 1

Stop position due to stop cause

Designated end

point position

Start point

address

Restart

Axis 2

Stop position

after restart

Operation

during restart

Axis 1

Stop position due to stop cause

Axis 2

Reference

If the positioning start signal [RY(n+1)0, [RY(n+1)1]/external start signal is turned

ON while the "Axis operation status (RWrn+7, RWrn+15)" is waiting or stopped,

positioning will be restarted from the start of the positioning start data regardless of

the absolute method or incremental method.

(Same as normal positioning.)

[Example for incremental method]

The positioning start operation when the axis 1 movement amount is 300 and the

axis 2 movement amount is 600 is shown below.

400

200

100

100 300 700

500

200

300 900

100

100

Axis 1

Stop position due to stop cause

Designated

end point

position

Start point

address

Axis 2

Axis 1

Stop position due to stop cause

Axis 2

Positioning

start

Stop position

after start

Operation dur-

ing positioning

start