12 - 77

MELSEC-

A

12 CONTROL AUXILIARY FUNCTIONS

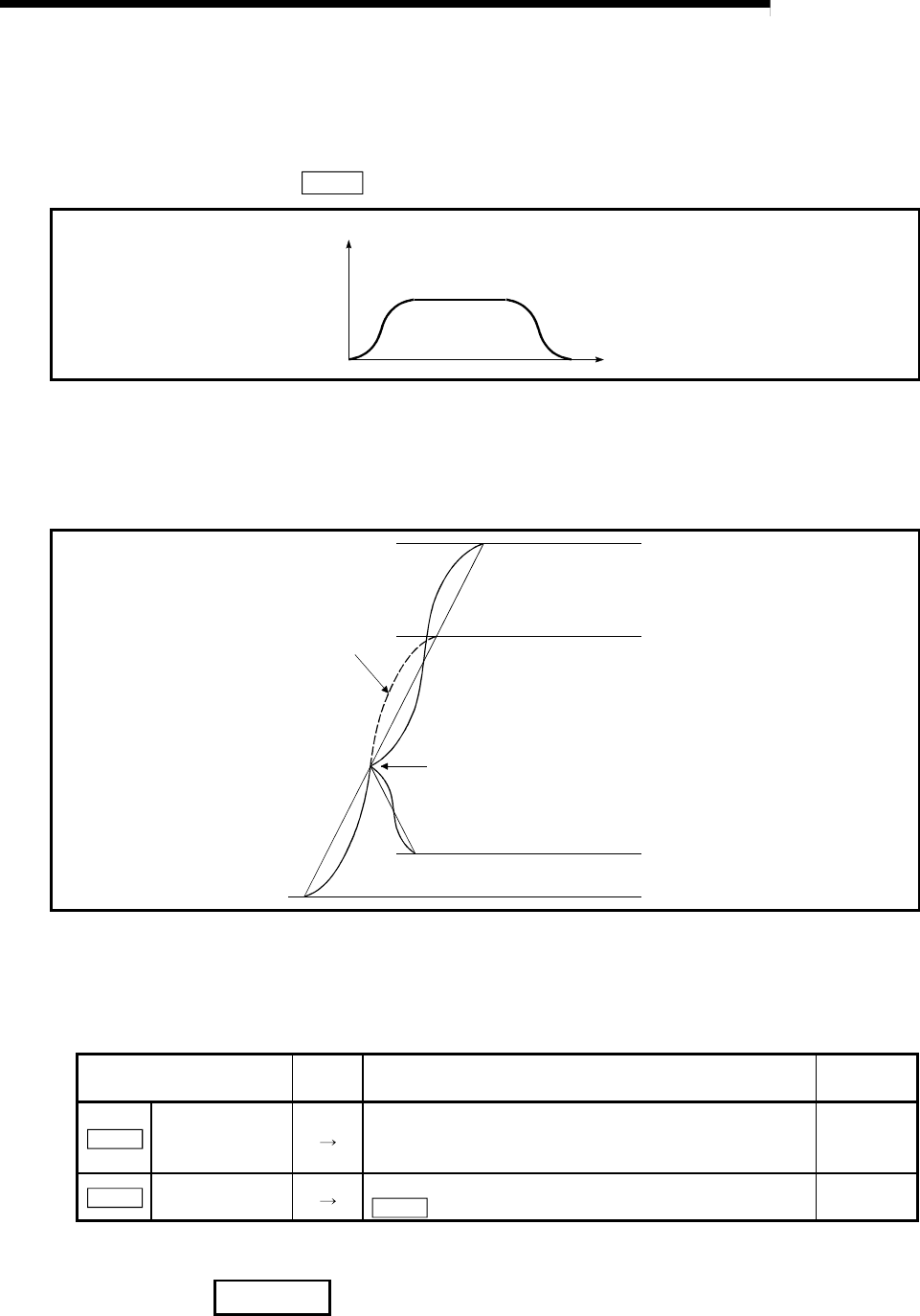

(b) S-curve acceleration/deceleration processing method

In this method, the motor burden is reduced during starting and stopping.

This is a method in which acceleration/deceleration is carried out gradually,

based on the acceleration time, deceleration time, speed limit value, and

"

Pr.36 S-curve ratio" (1 to 100%) set by the user.

V

elocity

Time

Fig. 12.43 S-curve acceleration/deceleration processing method

When a speed change request is made during S-curve

acceleration/deceleration processing, S-curve acceleration/deceleration

processing is performed from the start of the speed change request.

Speed change (acceleration)

Command speed before speed change

Speed change (deceleration)

Speed change erquest

When speed charge

request is not given

Fig. 12.44 S-curve acceleration/deceleration processing method

Set the required values for the "acceleration/deceleration method setting" in

the parameters shown in the following table, and write them to the D75P2.

The set details are validated when written to the D75P2.

Setting item

Setting

value

Setting details

Factory-set

initial value

Pr.35

Acceleration/

deceleration

process selection

Set the acceleration/deceleration method.

0: Automatic trapezoidal acceleration/deceleration method

1: S-curve acceleration/deceleration processing

0

Pr.36

S-curve ratio

Set the acceleration/deceleration curve when "1" is set in

"

Pr.35 Acceleration/deceleration processing selection".

100

* Refer to section "5.2 List of parameters" for setting details.

REMARK

Parameters are set for each axis.