3 - 8

MELSEC-

A

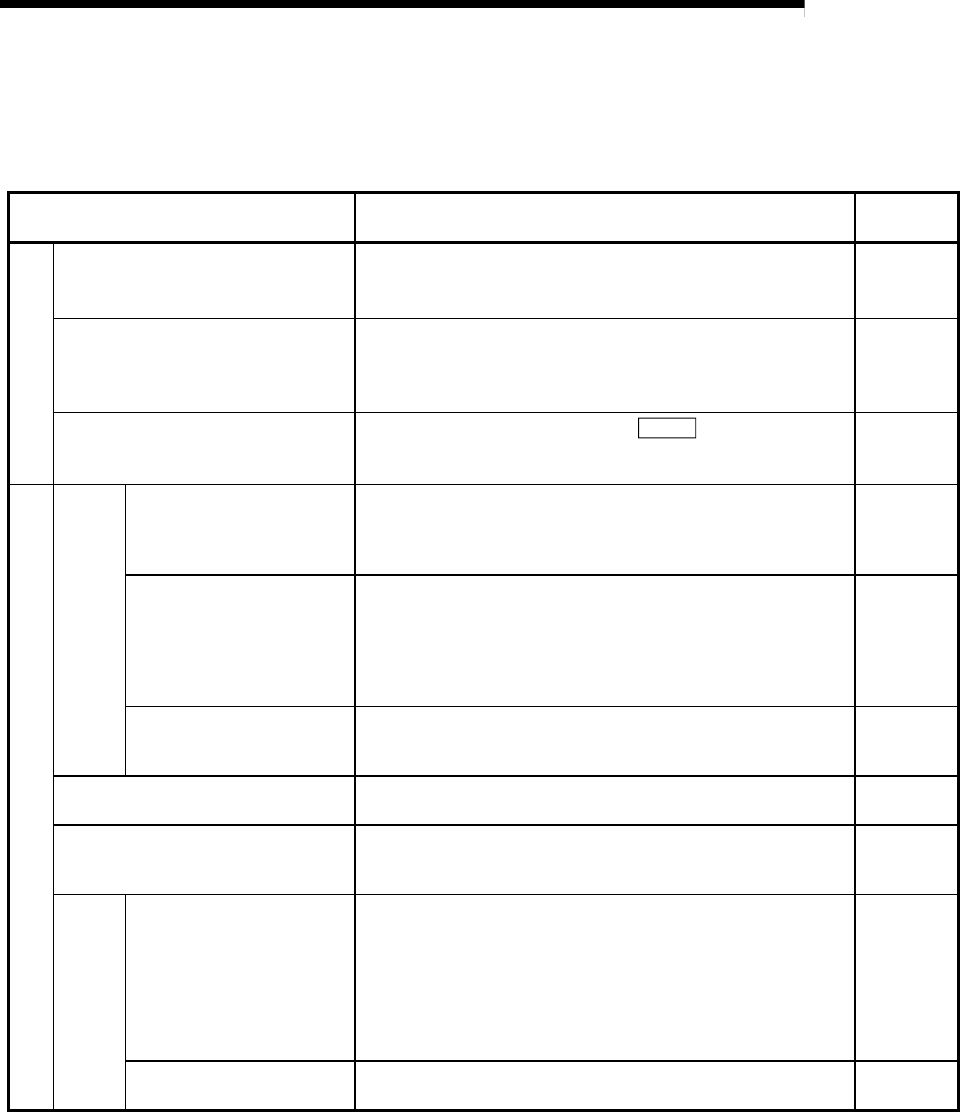

3 SPECIFICATIONS AND FUNCTIONS

3.3.2 D75P2 main functions

The outline of the main functions for positioning control with the D75P2 are described

below. (Refer to "SECTION 2" for details on each function.)

Main functions Details

Reference

section

Zero point return control

Machine zero point return control

Mechanically establishes the positioning start point with a near-

point dog or stopper. (Positioning start No. 9001)

8.2

Data setting method zero point return

Defines the position reached by manual operation as the zero

point address.

Used for an absolute position detection system.

(Positioning start No. 9901)

8.3

High-speed zero point return control

Positions to the zero point address (

Pr.47 ) stored in the

D75P2 with machine zero point return.

(Positioning start No. 9002)

8.4

Main positioning control

Position

control

Linear control

(1-axis linear control)

(2-axis linear interpolation

control)

Positions with a linear path to the address set in the positioning

data or the position designated with the movement amount.

9.2.2

9.2.3

Fixed-dimension feed

control

(1-axis fixed-dimension feed

control)

(2-axis fixed-dimension feed

control)

Positions the movement amount designated with the

movement amount set in the positioning data.

(With fixed-dimension feed control, the "Current feed value

(RWrn+0 to 1, RWrn+8 to 9)" is set to "0" when starting. With 2-

axis fixed-dimension feed control, the linear path will be fixed-

dimension fed with interpolation.

9.2.4

9.2.5

2-axis circular interpolation

control

Positions with an arc path to the address set in the positioning

data, or the position designated with the movement amount,

auxiliary point or center point.

9.2.6

9.2.7

Speed control

Continuously outputs the pulses corresponding to the

command speed set in the positioning data.

9.2.8

Speed/position changeover control

First, carries out speed control, and then carries out position

control (positioning of designated movement amount) by

turning the "speed/position changeover signal" ON.

9.2.9

Other

control

Current value change

Changes the

"Current feed value (RWrn+0 to 1, RWrn+8 to

9)

" to the address set in the positioning data.

The following two methods can be used.

(The machine feed value cannot be changed.)

Current value change using positioning data

Current value change using current value change start No.

(No. 9003)

9.2.10

JUMP command

Unconditionally or conditionally jumps to designated positioning

data No.

9.2.11