12 - 30

MELSEC-

A

12 CONTROL AUXILIARY FUNCTIONS

(4) Precautions during software stroke limit check

(a) A machine zero point return must be executed beforehand for the "software

stroke limit function" to function properly.

(b) During interpolation control, a stroke limit check is carried out for the current

values of both the reference axis and the interpolation axis. Neither axis will

start if an error occurs, even if it only occurs in one axis.

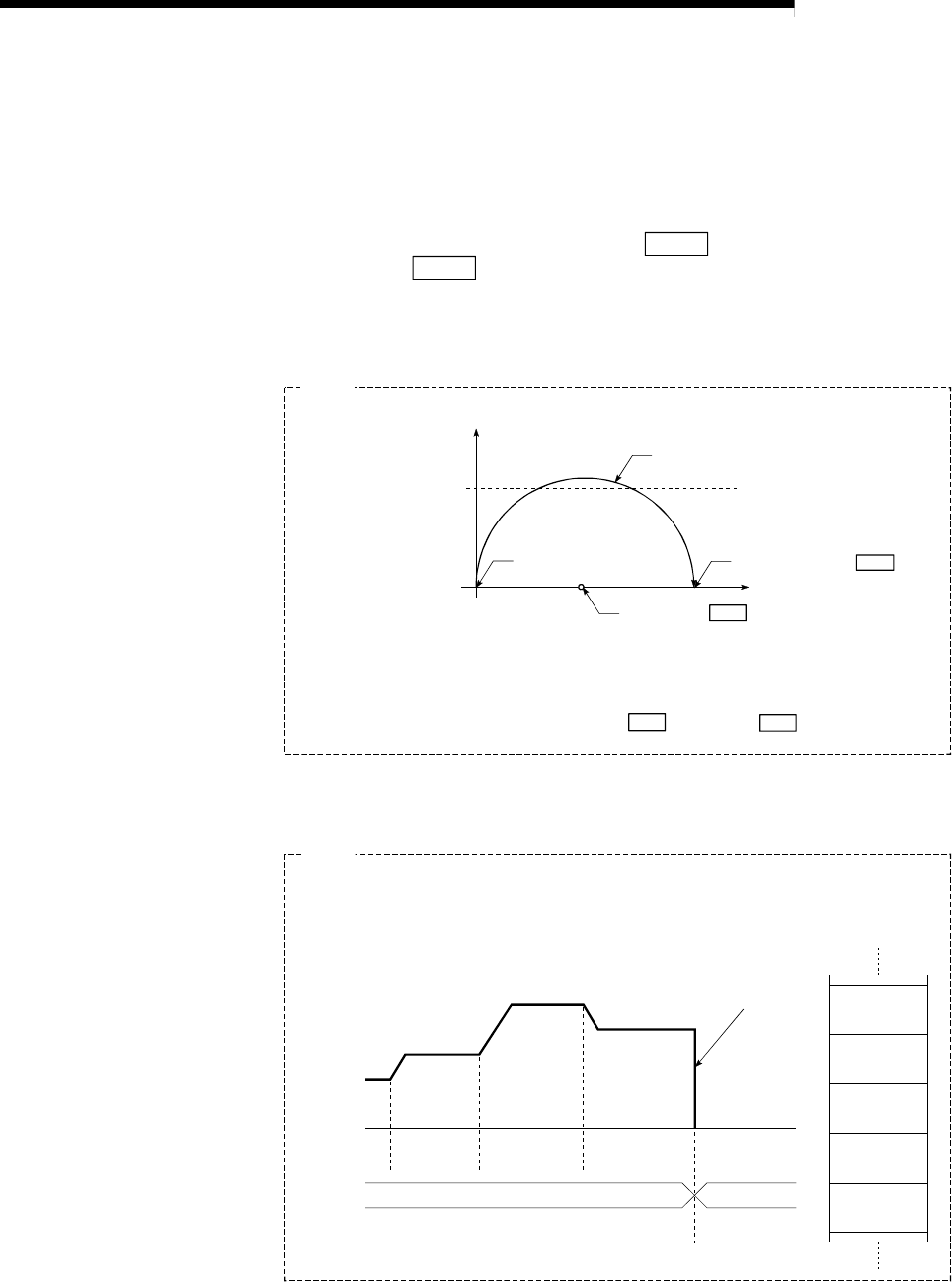

(c) During circular interpolation control, the "

Pr.13 Software stroke limit upper

limit value" / "

Pr.14 Software stroke limit lower limit value" may be

exceeded.

In this case, a deceleration stop will not be carried out even if the stroke limit

is exceeded. Always install an external limit switch if there is a possibility the

stroke limit will be exceeded.

Arc address ( Da. 6 )

End point address ( Da. 5 )

Axis 1

Axis 1 stroke limit

Deceleration stop not carried out

Starting address

* The software stroke limit check is carried out for the following addresses

during circular interpolation control.

Current value/end point address ( Da. 5 )/arc address ( Da. 6 )

Axis 2

Example

(d) If an error is detected during continuous path control, the operation will

immediately stop after the positioning data just before the positioning data

where the error occurred has been executed.

Axis operation status

No.10 No.11 No.12 No.13

Immediate stop at

error detection

No.10

P11

No.11

P11

No.12

P11

No.13

P11

No.14

P01

Controlling position

Error occurring

Positioning data

• If the positioning address of positioning data No. 13 is outside the software stroke limit range,

the operation immediately stops after positioning data No. 12 has been executed.

Example

(RWrn+7, RWrn+15)

(e) During simultaneous start, a stroke limit check is carried out for the current

values of both axes to be started. Neither axis will start if an error occurs,

even if it only occurs in one axis.